| Price | Negotiable |

| MOQ | 1SET |

| Delivery Time | 40-50 work days |

| Brand | JWIM |

| Place of Origin | China |

| Model Number | CC300-2 |

| Packaging Details | wooden case |

| Payment Terms | T/T |

| Place of Origin | China | Size | 1800×1760×3255mm |

| Packaging Details | wooden case | Material | Stainless Steel |

| Model Number | CC300-2 | Name | Pesticide Filling Machine |

| Brand Name | JWIM | Payment Terms | T/T |

| Filling Range | 200L | Delivery Time | 40-50 work days |

| Minimum Order Quantity | 1SET | Filling Accuracy | ±0.1% |

| Power Consumption | 1.7KW | Power | 380V 50Hz |

| Display | Touch Screen |

CC300-2

Fixed

Quantity

Weight

Filling

Machine

1.

Introduction

CC300-2

Fixed

Quantity

Weight

Filling

Machine

adopts

the

weighing

to

monitor

the

current

filling

quantity

in

real

time

and

feedback

to

the

controller,

which

outputs

fast

and

slow

filling

control

signals

according

to

the

set

data

to

achieve

fast

and

accurate

filling

of

big

containers.

It

can

meet

the

needs

of

a

variety

of

liquid

automatic

filling

both

with

and

without

foam.

2.Filling Container Information

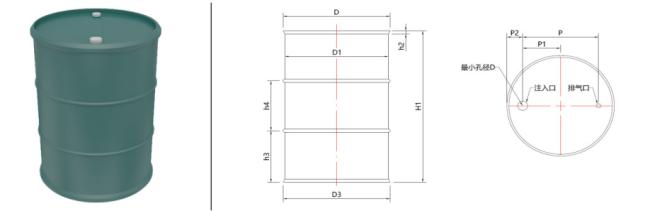

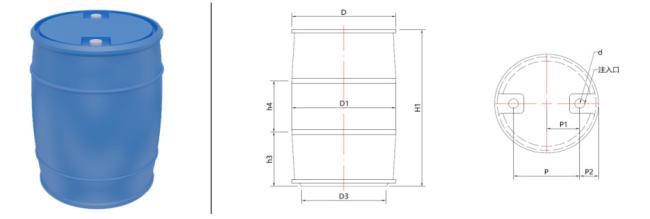

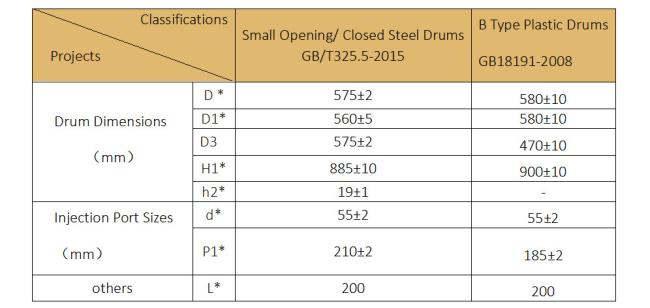

Small Opening/ Closed Steel Drums GB/T325.5-2015

B Type Plastic DrumsGB18191-2008

3.Technical Parameters

| 1 | Container Opening Diameter | Φ55-65mm |

| 2 | Container Diameter |

Refer to filling container information table. *Can accept customization. |

| 3 | Filling Range |

200L

|

| 4 | Division Value | 100g |

| 5 | Filling Precision |

±0.1% *①

|

| 6 | Capacity |

35-45Drums/hour(200L) *②

|

| 7 | Product Feeding Height | 2425mm |

| 8 | Min Opening Diameter | ≥Φ55mm |

| 9 | Air Pressure | 0.6-0.8MPa |

| 10 | Power Source | ~380V 50Hz/1.7KW |

| 11 | External Dimension | 1800×1760×3255mm (L×W×H) |

| 12 | Weight | About 1000Kg |

*① Marked accuracy is the accuracy of water test before the equipment leaves the factory.

The actual filling accuracy is different due to the influence of customer material viscosity, temperature, incoming pressure stability and other field conditions.

*② Marked capacity is based on testing capacity with water before the equipment leaves the factory;

The actual filling speed is due to the customer’s on-site incoming pipeline pressure and flow rate.

Material viscosity and foam factors are different; The difference in configuration requirements such as surface filling and under surface filling and bottom filling will also affect the actual production capacity.

4.Allocation

| No. | Name | Brand |

| 1 | Weighing System | METTLER TOLEDO |

| 2 | PLC | Schneider |

| 3 | HMI | Schneider |

| 4 | Inverter | Schneider |

| 5 | Counting Sensor | SICK |

| 6 | Proximity Switch | Schneider |

| 7 | Pressure Gauge | SMC |

| 8 | Cylinder | Air TAC |

| 9 | Solenoid Valve | FTEC |

| 10 | Button | Schneider |

| 11 | Alarm Light | Schneider |

| 12 | Circuit Breaker | Schneider |

5.Working process

Manual Drum Placing→Manual Cap Unloading→Auto Drum Feeding→Auto Mouth Seeking→Auto Filling→Drum Discharge→Manual Capping

6.Features

6.1

Two

empty

drums

come

into

the

filling

machine

as

a

unit.

The

drums

are

placed

by

the

roller,

filling

nozzle

automatically

aims

to

the

drum

opening,

filling

nozzle

going

down,

fast

&

slow

filling,

filling

valve

off,

nozzle

going

up

after

filling,

filled

drum

goes

out

and

enters

the

empty

drum.

6.2 High

Precision:

Weighing

filling

(US

Mettler

Toledo

Weighing

Sensor)

to

make

sure

the

high

filling

precision.

6.3 The

filling

head

is

equipped

with

a

rotating

liquid

cup.

After

filling,

the

liquid

cup

will

collect

the

residual

material

on

the

filling

head

to

prevent

the

product

from

leaking

and

contaminating

the

container.

6.4 Fast

and

slow

filling

valve

is

adopted

to

ensure

the

accuracy

of

filling

without

affecting

the

overall

filling

speed.

With

filling

nozzle

diving

mechanism,

it

can

both

fill

on

or

under

liquid

surface,

suitable

for

filling

products

with

no

foam

or

slight

foam.

6.5

Adopting

a

connecting

rod

mechanism

driven

by

two

cylinders

on

both

sides

to

achieve

the

separation

and

blocking

of

empty

barrels,

ensuring

more

precise

and

firm

positioning.

When

the

filling

machine

is

completed

and

the

full

barrel

is

conveyed

to

the

next

station,

the

drum

blocking

cylinder

retracts

and

the

empty

barrel

enters

the

filling

machine.

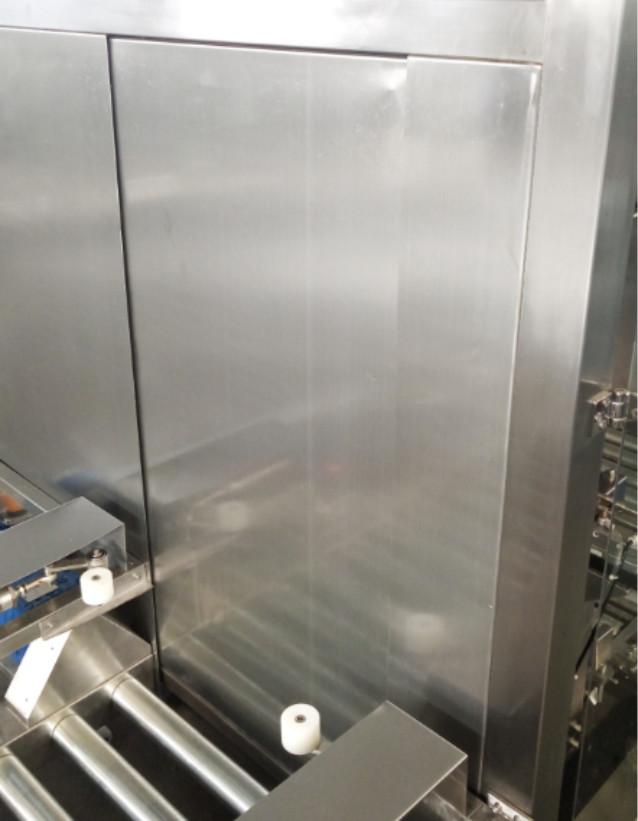

6.6

Automatic

sliding

door:

The

empty

bucket

is

manually

placed

on

the

feeding

roller.

When

the

photoelectric

sensor

detects

the

presence

of

a

bucket,

the

sliding

door

automatically

opens

and

transports

the

empty

bucket

to

the

automatic

mouth

finding

station.

(This

function

is

optional)

6.7 The

machine

uses

France

Schneider

Control

system

to

control

the

operating

stability.

Meanwhile,

the

control

system

is

with

low

energy

consumption.

Compared

with

various

miscellaneous

brands

used

by

other

manufacturers,

France

Schneider

Control

system

has

a

high

level

of

protection,

stable

reliability

and

safety

level,

service

life,

especially

in

the

follow-up

upgrade

of

the

matching

more

advantages.

7.Support and Services:

Our

technical

support

and

services

for

the

Pesticide

Filling

Machine

are

designed

to

provide

the

most

comprehensive

assistance

for

our

customers.

Our

team

of

experienced

engineers

and

technicians

are

available

to

provide

assistance

with

installation,

maintenance,

troubleshooting,

and

repair

services.

We

offer

in-house

training

on

the

operation

and

maintenance

of

the

machine

to

ensure

that

our

customers

can

get

the

most

out

of

their

purchase.

Additionally,

we

provide

online

support

through

our

website,

which

includes

FAQs,

product

manuals,

and

other

helpful

resources.

If

you

ever

have

any

questions

or

concerns

about

the

Pesticide

Filling

Machine,

our

team

of

experts

are

available

to

help.

We

believe

that

customer

satisfaction

is

our

top

priority,

and

we

strive

to

provide

the

best

technical

support

and

services

possible.

8.Packing

and

Shipping:

The

Pesticide

Filling

Machine

will

be

securely

packaged

in

a

cardboard

box

to

protect

it

during

shipping.

We

will

use

a

reliable

carrier

to

ship

the

product

to

the

customer's

address.

9.FAQ: