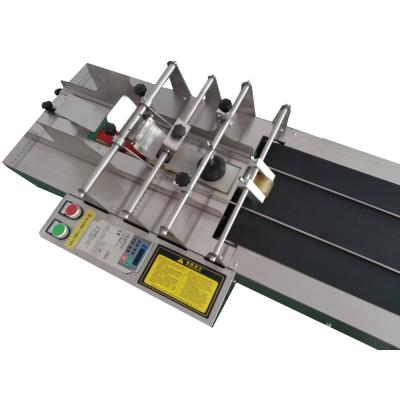

DIKAI

WF420

Updraft

Paging

machine

can

be

equipped

with

ribbon

printer,

ink

wheel

printer,

heat

transfer

printer,

jet

printer

and

laser

printer.

It

contains

cable-stayed

alignment

device

that

paging

bags

are

aligned

to

improve

the

position

accuracy

of

the

code

and

label.

The

negative

pressure

suction

device,

effectively

ensure

that

the

bags

after

paging

are

conveyed

smoothly

on

the

conveyor

belt,

and

ensure

the

accurate

position

of

spray

code

and

labeling.

And

De-static

device:

Ionic

wind

can

remove

the

static

electricity

on

the

surface

of

products,

effectively

avoid

the

products

adsobing

together.

This

"TTO

thermal

transfer

integrated

machine"

is

based

on

the

current

"standard

TTO

paging

machine",

aiming

at

the

current

plastic

packaging

bags

for

seeds,

agrochemicals

and

food.

And

re-integrated,

optimized

and

specially

developed.

According

to

the

coding

requirements

of

"one

thing,

one

code"

for

packaging

products

and

combining

the

coding

characteristics

of

different

industries,

Strive

for:

"one

machine

is

multi-purpose-to

meet

the

paging

and

coding

of

various

films

and

labels";

"One

machine

is

versatile–TTO

thermal

transfer

printer

and

hot

foaming

spray

can

be

installed.

Code

machine

or

UV

jet

printing

system

";

"One

machine

is

diversified-the

structure

is

modularized,

and

various

configurations

are

selected

according

to

needs",

in

short,

all

kinds

of

plastic

packaging

products

are

coded.

The

ideal

choice

for

jet

printing!

Suitable

products:

paper

and

film

labels,

plastic

packaging

bags

and

composite

films.

Suitable

product

types:

plastic

bags/films,

labels,

varnish

or

coated

paper

products.