| Price | Negotiable |

| MOQ | 1 set |

| Delivery Time | 90 days after all the technical requirements are confirmed |

| Brand | GWELL |

| Place of Origin | China |

| Certification | CE |

| Model Number | GWC92/188,GWC80/156 |

| Packaging Details | STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS |

| Payment Terms | L/C, T/T |

| Supply Ability | 200 sets/yr |

| Place of Origin | China | Warranty | One year |

| Packaging Details | STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS | Model Number | GWC92/188,GWC80/156 |

| Supply Ability | 200 sets/yr | Certification | CE |

| Brand Name | GWELL | Payment Terms | L/C, T/T |

| Brand | GWELL | Thickness | 1.5-5mm |

| Screw design | conical twin screw | After-sales service | installation and machine debug |

| Country of origin | China | Price | Negotiable |

| Delivery Time | 90 days after all the technical requirements are confirmed | Product name | LVT Wood Plastic Floor Extrusion Line LVT Flooring Production Machine Twin Screw Extruder |

| Machine type | Composite plastic floor extrusion line | Minimum Order Quantity | 1 set |

| Suitable material | LVT | Width | 1000mm |

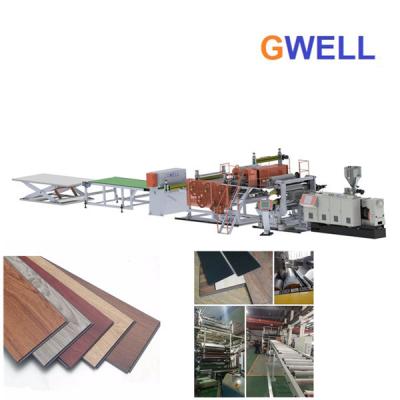

LVT Wood Plastic Floor Extrusion Line LVT Flooring Production Machine Twin Screw Extruder

1. Introduction of LVT Wood Plastic Floor Extrusion Line

The production process of LVT Wood Plastic Floor Extrusion Line of GWELL company is:

(1) The raw material will be automatic fed into high-speed mixing,

(2) Then it is automatically fed into the twin-screw extruder,

(3) Then the melt material will be extruded out from the T-die which is special for plate,

(4) After going through the T-die, the plate will be formed by the calibration table and cooled by cooling brackets,

(5) Then the board will be through the edge trimming unit, traction unit, automatic cutting unit, automatic lifting unit, roller conveyor, etc.

The unit has a compact structure and superior performance.LVT Wood Plastic Floor Extrusion Line

The screw and barrel are optimized and processed with high-performance alloy steel, so that the whole machine has the advantages of uniform plasticization, stable extrusion, high output, and long life. The main barrel is heated by cast aluminum heater, cooled by air, and the temperature is controlled by precision electronic control instrument. LVT Wood Plastic Floor Extrusion Line

2. Process of LVT Wood Plastic Floor Extrusion Line

Floor materials such as LVT Wood Plastic Floor Extrusion Line, mixed by high speed mixer mixing and delivered by rotating conveyor to the conical twin-screw extruder, then extuded by T die and attach the wear-resisting layer and printing layer to the product with specified thickness. Extrusion laminating process can replace the traditional rolling, laminated and complex process. It is easy to operate, has low investment cost, and can reduce the labor intensity of workers. Also it can keep workshop clean, and the production line will adopt optical sensor detection and alarm, so it has a high degree of automation.LVT Wood Plastic Floor Extrusion Line

3. LVT Flooring Production Machine

In 2013, Gwell successfully developed LVT Flooring Production Machine, and realized one-time lamination of LVT Flooring Production Machine, which improved production line efficiency and quality stability. It has been exported to some countries in Europe and America. Because its design and color are rich, it is popular to be used at home outfit and commercial domain.

4. Configuration of LVT Flooring Production Machine:

| Type of extruder | Conical twin-screw extruder GWC80/156 | Conical twin-screw extruder GWC92/188 | Parallel twin-screw extruder GWP75/36 |

| Width of product | 1000mm | 1000mm | 1000mm |

| Thickness of product | 1.5mm-2mm | 2mm-5mm | 1.5mm-5mm |

| Output | 350kg/h-400kg/h | 550kg/h-650kg/h | 400kg/h-500kg/h |

Gwell

plastic

transparent

sheet

unit

production

line

absorbs

and

digest

western

country

advanced

extrusion

technology.

And

its

main

parts

choose

from

all

over

the

world

(such

as

screw,

barrel,

roller,

etc.).

The

energy

consumption

of

its

complete

sets

of

equipment

,

intelligent,

automation,

safety

standard,

technology

standard,

etc.,

have

been

at

or

near

the

world

standard

of

the

product.

This

series

of

products

has

a

number

of

inventions

and

utility

model

patents

so

that

it

replaces

imported

equipment,

and

has

a

cost-effective

advantage.

The

high-level

transparent

plate

products

are

widely

used

in

optics,

home

appliances,

construction

engineering,

decoration,

furniture,

advertising,

handicrafts

and

other

industries

and

civil

industries.

Its

quality

has

reached

the

world's

product

performance,

and

we

have

a

matching

team

of

experts

and

process

engineers

to

help

users

debug,

produce

high-quality

products.