| Price | Negotiable |

| MOQ | 1 set |

| Delivery Time | 90 days for the whole produciton period |

| Brand | GWELL |

| Place of Origin | China |

| Certification | CE |

| Model Number | GWS120/GWS160/GWS180 |

| Packaging Details | STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS |

| Payment Terms | L/C, T/T |

| Supply Ability | 200 sets per year |

| Origin | China | Place of Origin | China |

| Die lip gap | 0.5/0.7mm(depends on customers) | Packaging Details | STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS |

| Color | white , semi-transparent | Film structure | single layer film |

| Service | technical support , machine drawing , installation , machine testing | Model Number | GWS120/GWS160/GWS180 |

| Supply Ability | 200 sets per year | Certification | CE |

| Brand Name | GWELL | Payment Terms | L/C, T/T |

| Brand | GWELL | Screw design | Single screw design |

| Price | Negotiable | Delivery Time | 90 days for the whole produciton period |

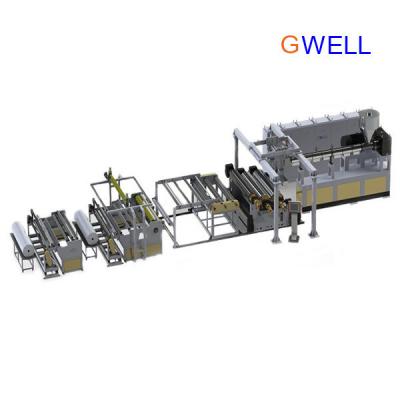

| Product name | Poe Cast Film Extrusion Machine PV Encapsulation Extrusion Poe Film Machine | Machine type | cast film machine/PV solar film machine |

| Minimum Order Quantity | 1 set | Suitable material | EVA/POE |

| Width | 2200mm 2400mm 2600mm 3000mm |

Poe

Cast

Film

Extrusion

Machine

PV

Encapsulation

Extrusion

Poe

Film

Machine

1.

Introduction

of

EVA/POE

solar

film

extrusion

line

(1)

Special

EVA

encapsulating

film

for

solar

modules

(photovoltaic

modules)

and

related

solar

products

is

used

to

encapsulate

solar

panels,

which

is

non-sticky

at

room

temperature

and

easy

to

operate.

After

hot

pressing,

thermal

cross-linking

will

occur

due

to

chemical

and

bonding

enhancement

reaction

to

produce

a

permanent

adhesive

seal.

Product

features:

high

light

transmittance/high

adhesion

strength/high

light

and

heat

stability/superior

volumetric

electricity

group

rate.

(2)

Compared

with

EVA

film

extrusion

line,

the

biggest

advantage

of

POE

film

extrusion

line

is

low

water

vapor

transmission

rate

and

high

volume

resistivity,

which

ensures

the

safety

and

long-term

aging

resistance

of

the

module

in

high

temperature

and

high

humidity

environment,

and

ensures

long-term

use

of

components.

Specifically,

the

superior

performance

of

the

POE

film

relative

to

the

EVA

film

is

that

the

POE

film

is

a

copolymer

of

ethylene

and

octene,

is

a

saturated

fatty

chain

structure,

and

has

fewer

tertiary

carbon

atoms

in

the

molecular

chain,

showing

good

weather

resistance,

UV

aging

resistance,

excellent

heat

resistance

and

low

temperature

resistance,

so

POE

film

extrusion

line

has

better

aging

resistance

than

EVA

film.

Through

modification

methods

such

as

photo-grafting

polar

monomer,

plasma

surface

treatment

or

reactive

grafting

modification

to

POE,

it

can

improve

the

adhesion

of

POE

film extrusion

line

and

glass,

backplate

and

other

materials,

and

has

excellent

interfacial

adhesion

performance.

(3)

It

is

suitable

for

high-efficiency

double-sided

batteries,

which

can

effectively

enhance

the

conversion

efficiency

of

the

battery.

Compared

with

ordinary

single-sided

power

generation

modules,

it

increases

the

power

generation

rate

and

reduces

the

cost

of

electricity.

At

the

same

time,

the

modules

can

be

placed

vertically

and

have

more

utilization

methods.

The

POE

film

has

a

lower

water

vapor

transmission

rate

and

greater

cohesion.

It

is

more

suitable

for

double-glass

modules,

so

that

the

produced

double-glass

modules

do

not

require

edge

sealing

and

have

a

longer

service

life.

2.

Features

of

EVA

solar

film extrusion

line

(1)

High

transparency

and

high

adhesion

can

be

applied

to

various

interfaces

and

used

for

bonding

glass

and

silicon

wafers.

(2)

Good

durability

can

resist

high

temperature,

moisture,

ultraviolet

rays

and

so

on.

(3)

Easy

to

store.

Stored

at

room

temperature,

the

adhesion

of

EVA

is

not

affected

by

humidity

and

water-absorbent

film.

3.

Characteristics

of

POE

polyolefin extrusion

line

(1)

POE

has

the

general

characteristics

of

thermoplastic

elastomers.

The

soft

chain

curling

structure

of

octene

and

the

crystalline

vinyl

chain

are

used

as

physical

crosslinking

points,

making

it

both

excellent

toughness

and

good

processability;

(2)The

price

is

low

and

the

relative

density

is

small,

so

the

volume

and

price

are

low;

(3)

Excellent

heat

resistance

and

cold

resistance,

and

a

wide

using

temperature

range;

(4)

Weather

resistance,

good

aging

resistance,

because

there

are

no

unsaturated

double

bonds

in

the

molecular

structure

of

POE

plastics,

it

has

excellent

aging

resistance;

(5)

Oil

resistance,

compression

permanent

deformation

and

abrasion

resistance

are

not

good;

(6)

POE

plastics

have

narrow

molecular

amount

distribution,

good

fluidity,

and

good

compatibility

with

polyolefins;

(7)

Good

fluidity

can

improve

the

dispersing

effect

of

the

filler

and

at

the

same

time

increase

the

weld

line

strength

of

the

product.

4.

Specification:

| Extruder type | GWS160 | GWS160 | GWS180 | GWS180 |

| raw material | EVA ,POE | EVA ,POE | EVA ,POE | EVA,POE |

| Product width | 2200mm, 2400mm, 2600mm | |||

| Product thickness | 0.2mm -1mm | 0.2mm -1mm | 0.2mm -1mm | 0.2mm -1mm |

| Maximum linear speed | 10m/min ,12m/min,15m/mn | |||

| Extruder type | Co-extrusion GWS160+GWS160 | Co-extrusion GWS180+GWS160 | Co-extrusion GWS180+GWS180 |

| raw material | EVA ,POE | EVA ,POE | EVA,POE |

| layers | A,A/B/A | ||

| Product width | 2400mm,2600mm | ||

| Product thickness | 0.2mm -1mm | 0.2mm -1mm | 0.2mm -1mm |

| Maximum linear speed | 15m/min, 16m/mn, 18m/min | ||

Suzhou branch factory

Yancheng branch factory

Option

1

(Concise

&

Benefit-Focused):

Unlock

Solar

Film

Production

Flexibility

|

GWELL

Co-Extrusion

Line

Maximize

your

PV

module

encapsulant

output

with

GWELL's

advanced

co-extrusion

line.

Engineered

for

high-performance

EVA,

POE,

and

EPE

solar

films,

our

technology

delivers

precision

thickness

control,

blistering

speeds,

and

unmatched

reliability.

Boost

productivity

&

quality

for

superior

module

encapsulation.

Option

2

(Solution-Oriented

&

Keyword

Rich):

GWELL

EVA/POE/EPE

Solar

Film

Co-Extrusion

Line:

Your

All-in-One

Solution

Streamline

production

of

high-quality

PV

module

encapsulation

films

(EVA,

POE,

EPE)

with

GWELL's

innovative

co-extrusion

line.

Achieve

exceptional

layer

adhesion,

precise

gauge

control,

and

high

throughput

while

reducing

operational

costs.

Engineered

for

dependable,

automated

solar

film

manufacturing.

Option

3

(Feature

Highlighting

&

Technology

Focus):

Cutting-Edge

Co-Extrusion

for

Premium

Solar

Encapsulation

|

GWELL

The

GWELL

EVA/POE/EPE

Co-Extrusion

Line

sets

the

standard

for

producing

multi-layer

encapsulant

films

critical

for

durable,

high-efficiency

solar

panels.

Featuring

automatic

gauge

control,

optimized

melt

homogeneity,

integrated

cooling

&

winding,

it

ensures

consistent

perfection

for

EVA,

POE,

or

EPE

formulations.

Option

4

(Benefit-Driven

&

Audience

Focused):

Empower

Your

Solar

Film

Production

with

GWELL

Co-Extrusion

Meet

soaring

demand

for

EVA,

POE,

and

EPE

encapsulation

films.

GWELL's

co-extrusion

line

provides

reliable,

high-volume

production

of

defect-free

films

with

superior

surface

quality

and

UV

stability.

Achieve

lower

production

costs

&

faster

time-to-market.

Scale

your

PV

supply

chain

efficiently.

Why

Choose

GWELL?

✅

Turnkey

Solutions

–

From

installation

to

after-sales

support

✅

Global

Installations

–

Trusted

by

500+

clients

across

30+

countries

✅

Fast

ROI

–

High

yield

and

low

waste

maximize

profitability

Ready

to

Boost

Your

Production?

Contact

Our

Experts

Today!

Liam:

saled@gwell.cn

|

+86

15906224102

Max:salem@gwell.cn

|

+86

15906227399