| MOQ | 25 |

| Delivery Time | 25 |

| Brand | BHP-240Z |

| Place of Origin | CHINA |

| Certification | CE |

| Model Number | BHP-240Z |

| Packaging Details | Wooden Case |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 25 |

| bag shape: | zipper bag/doypack | Place of Origin | CHINA |

| Automatic Grade: | Automatic | Packaging Details | Wooden Case |

| Model Number | BHP-240Z | Supply Ability | 25 |

| Certification | CE | Brand Name | BHP-240Z |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram | additional function | hanging hole,special shape |

| Price | Delivery Time | 25 | |

| Minimum Order Quantity | 25 | Type: | Packing Machine |

| Application | food,daily chemical etc | Dimension(L*W*H): | 2000*1200*2400MM |

Full automatic Rotary Premade Bag Chips Snack Packing Machine

Machine working process

1. Bag pick-up

2. Optional Zipper open and Date print

3. Bag mouth and bottom open

4. Product fill

5. Option: Solid :Nitrogen charge,Powder:Bag mouth clean,

Liquid:Secondary filling

6. First seal

7. Second seal

8. Output

Products Description

One machine for your current and future needs! The versatility of DESSION pouch packing machines for the filling and sealing of stand up bags allows you to customize your machine to meet the current needs of the market and your individual technical requirements!

Using DESSION Stand-up Pouch packing machines for packaging premium pieced products and powdered products into doy pack bags and zipper doy pack bags, such as coffee, tea, biscuits, nuts, cereals, chips and many others.

Details

Fully automated packaging machine with automatic weighing, filling, date printing and sealing. To change bags of different sizes, just adjust the bag holder and modify the parameters on the screen. Simple operation.

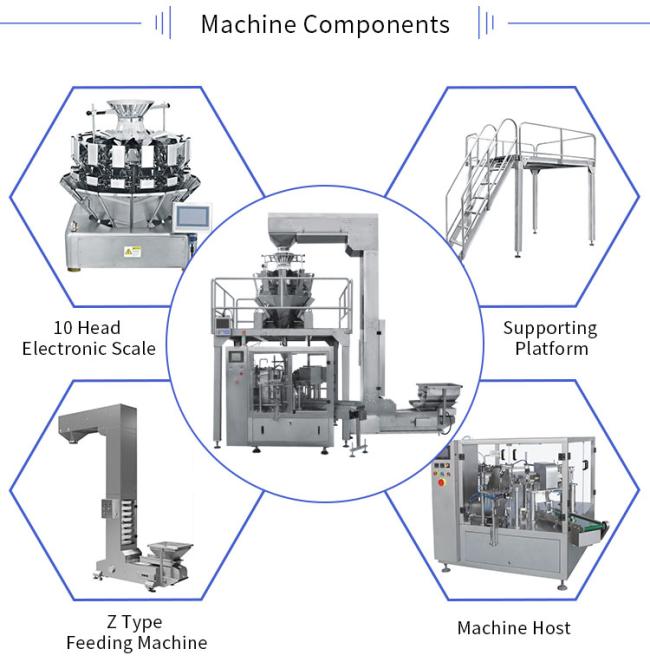

1. 10 Head Electronic Scale

The product accurately weighs the required weight through an electronic scale.

2. Bag Given Device

Depending on the size of the bag, the size of the bag holder can be customized or adjusted so that the machine can grab the bag.

3. Date printer

Set the corresponding date on the screen as required, and the machine will automatically print on the bag.

4. Bag Opening Device

Through the suction ports on both sides of the devi.ce, the bag can be opened quickly and efficiently.

5. Feeding Hopper

The weighed product enters the bag through the filling hopper.

6. Sealing Device

The sealing device is sealed by a high-temperature mold.

Technical Specifications:

|

Working position |

eight-working position |

|

Pouch material |

Laminated film PE,PP |

|

Pouch pattern |

stand-up&zipper pouch |

|

Pouch size |

W:100-210mm L:100-350mm |

|

Filling Scope |

10-5000g( The screw attachment is to be changed) |

|

Weight Accuracy

|

Package weight ≤ 100g, with an error≤±2% 100 — 500g,with an error≤±1% ≥500G error≤±0.5% |

|

Speed |

10-45pouches/min(The speed depends on the product status and flling weight)) |

|

Voltage |

380V 3phase 50HZ/60HZ |

|

Total power |

8.5KW |

|

Compress air |

0.6m3/min(supply by user) |