| Price | Negotiable |

| MOQ | 1000PCS |

| Delivery Time | 5-7 days |

| Brand | TIAN RUI |

| Place of Origin | China |

| Certification | ROHS REACH |

| Model Number | 3R-3S |

| Packaging Details | 1000pcs/PE bag |

| Payment Terms | D/P,T/T,Paypal,Western Union |

| Supply Ability | 1000000+PCS+Month |

| Place of Origin | China | Size | 3.5mm*3.5mm*6.8mm |

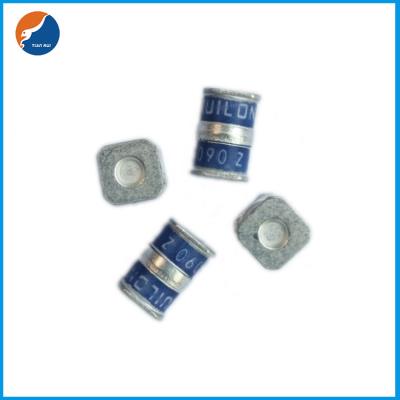

| Packaging Details | 1000pcs/PE bag | Product Name | 3R-3S Gas Discharge Tubes |

| 8/20μs Impulse Current | 2KA | Tolerance | 30% |

| Electrode Numbers | 3 Electrodes | Model Number | 3R-3S |

| Supply Ability | 1000000+PCS+Month | Lead Type | SMD |

| Certification | ROHS REACH | Weight | 0.3g |

| Brand Name | TIAN RUI | Payment Terms | D/P,T/T,Paypal,Western Union |

| Price | Negotiable | Delivery Time | 5-7 days |

| Minimum Order Quantity | 1000PCS | DC Spark-Over Voltage | 90V-470V |

| Ultra Low Capacitance | Max 1pF | Application | industrial equipment |

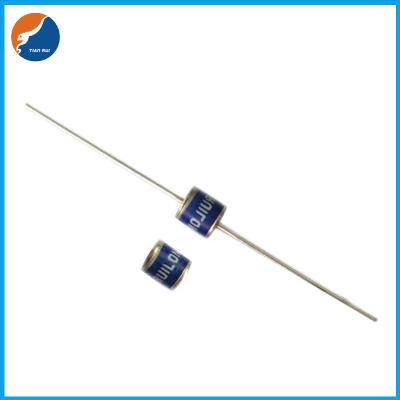

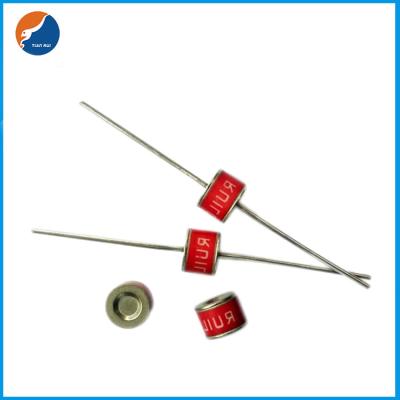

3R-3S Ceramics Surge Protection 3 Electrode Gas Discharge Tubes GDT For High Bandwidth Applications

Description of 3R-3S Ceramics Surge Protection 3 Electrode Gas Discharge Tubes GDT For High Bandwidth Applications

Gas discharge tubes (GDT) use noble gasses enclosed in ceramic tubes to provide an alternate circuit path for voltagespikes. The ceramic envelope and with nickel connectors allow for high loads. 3R-3S Gas Discharge Tubes (GDT) series has a surge rating of 2kA, 8/20μs.Offered in a Squared Surface Mount package, which helps to make pick and place on PCB process easier.

This

GDT

series

is

perfectly

suited

for

broadband

equipment

applications.

The

GDT’s

low

off-state

capacitance

is

compatible

with

high

bandwidth

applications

and

this

capacitance

loading

value

does

not

vary

if

the

voltage

across

the

GDT

changes.

3R-3S

Gas

Discharge

Tube

(GDT)

series

are

specifically

designed

for

protection

of

electrical,

multimedia,

and

communication

equipment

against

over

voltage

transients

in

surface

mount

assembly

applications.

Features of 3R-3S Ceramics Surge Protection 3 Electrode Gas Discharge Tubes GDT For High Bandwidth Applications

•

Extremely

small

size

•

Excellent

response

to

fast

rising

transients

•

Stable

breakdown

voltage

•

GHz

working

frequency

•

8/20μs

Impulse

current

capability:

2KA

•

Surface

Mount

package

•

Non-Radioactive

•

Ultra

Low

capacitance

(<1pF)

•

High

insulation

resistance

•

Lead-free

compliant

•

RoHS

and

REACH

compliant

•

Size:

3.5mm*3.5mm*6.8mm

•

Storage

and

operational

temperature:

-40~+90°C

Applications of 3R-3S Ceramics Surge Protection 3 Electrode Gas Discharge Tubes GDT For High Bandwidth Applications

•

Communication

equipment

•

CATV

equipment

•

Data

lines

•

Telecom

SLIC

protection

•

Broadband

equipment

•

ADSL

equipment,

including

ADSL2+

•

XDSL

equipment

•

Satellite

and

CATV

equipment

•

Test

equipment

•

Consumer

electronics

•

ESD

protection

Electrical Characteristics of 3R-3S Ceramics Surge Protection 3 Electrode Gas Discharge Tubes GDT For High Bandwidth Applications

| Part Number |

DC Spark-over Voltage 1) 2) 3) @100V/S |

Impulse Spark-over Voltage 3) |

Insulation

Resistance 3) 4) |

Capacitance

@1MHz 3) |

Glow

Voltage

@10mA 3) |

Arc

Voltage

@1A 3) |

Life Ratings | ||||||||||||||||||||||||||||

|

Impulse

Discharge

Current @8/20μs 5) |

Impulse

Discharge

Current @8/20μs 6) |

Impulse

Withstanding

Voltage

Capacity

@10/700μS,

40 ±5 times 7) |

|||||||||||||||||||||||||||||||||

| 100V/μS | 1KV/μS | ||||||||||||||||||||||||||||||||||

| Max | Max | Min | Max | Type | Type |

Nominal ±5 times |

Max 1 time | Nominal 300 times | |||||||||||||||||||||||||||

| V | V | V | GΩ | pF | V | V | KA | KA | A | KV | |||||||||||||||||||||||||

| 3R090F-3S | 90±30% | 500 | 600 | 1 | 1 | 60 | 10 | 2 | 3 | 100 | 6 | ||||||||||||||||||||||||

| 3R150F-3S | 150±30% | 500 | 600 | 1 | 1 | 60 | 10 | 2 | 3 | 100 | 6 | ||||||||||||||||||||||||

| 3R200F-3S | 200±30% | 600 | 700 | 1 | 1 | 60 | 10 | 2 | 3 | 100 | 6 | ||||||||||||||||||||||||

| 3R230F-3S | 230±30% | 600 | 700 | 1 | 1 | 60 | 10 | 2 | 3 | 100 | 6 | ||||||||||||||||||||||||

| 3R350F-3S | 350±30% | 800 | 900 | 1 | 1 | 60 | 15 | 2 | 3 | 100 | 6 | ||||||||||||||||||||||||

| 3R400F-3S | 400±30% | 850 | 950 | 1 | 1 | 60 | 15 | 2 | 3 | 100 | 6 | ||||||||||||||||||||||||

| 3R420F-3S | 360-560 | 850 | 950 | 1 | 1 | 60 | 15 | 2 | 3 | 100 | 6 | ||||||||||||||||||||||||

| 3R470F-3S | 470±30% | 900 | 1000 | 1 | 1 | 60 | 15 | 2 | 3 | 100 | 6 | ||||||||||||||||||||||||

| Glow to Arc transition Current…………………………………………................... ~0.3A | |||||||||||||||||||||||||||||||||||

| Weight ~0.30g | |||||||||||||||||||||||||||||||||||

| Operation and storage temperature…………………………………..................... -40~+90°C | |||||||||||||||||||||||||||||||||||

| Climatic category (IEC 60068-1) 40/90/21 | |||||||||||||||||||||||||||||||||||

| Marking………………………………………………………………….................... Without | |||||||||||||||||||||||||||||||||||

| Surface treatment Matte-tin plated | |||||||||||||||||||||||||||||||||||

|

1)

At

delivery

AQL

0.65

level

II,

DIN

ISO

2859 2) In ionized mode 3) Tip or ring electrode to center electrode 4) Insulation Resistance Measuring Voltage: 90V~150V at DC 50V Other at DC 100V 5) Total current through center electrode, half value through tip respectively ring electrode. 6) Tip to ring electrode. 7) Tip to center electrode additional ring to center electrode. Terms in accordance with ITU-T Rec. K.12, IEC 61643-311, GB/T 9043. |

|||||||||||||||||||||||||||||||||||

| Symbol | Millimeters | Inches | |||||||||||||||||||

| A | 3.5±0.2 | 0.138±0.008 | |||||||||||||||||||

| B | 3.5±0.2 | 0.138±0.008 | |||||||||||||||||||

| C | 6.8±0.3 | 0.268±0.012 | |||||||||||||||||||

| D | 1.2±0.3 | 0.047±0.012 | |||||||||||||||||||

| E | 0.4±0.2 | 0.016±0.008 | |||||||||||||||||||

| F | 0.4±0.2 | 0.016±0.008 | |||||||||||||||||||

| X | 1.4 | 0.055 | |||||||||||||||||||

| X1 | 1.8 | 0.071 | |||||||||||||||||||

| X2 | 6.7 | 0.264 | |||||||||||||||||||

| Y | 4.2 | 0.165 | |||||||||||||||||||

| Symbol | Millimeters | Inches | |||||||||||||||||||

| W | 16±0.3 | 0.630±0.012 | |||||||||||||||||||

| A0 | 3.8±0.1 | 0.154±0.004 | |||||||||||||||||||

| B0 | 7.0±0.1 | 0.276±0.004 | |||||||||||||||||||

| K0 | 3.7±0.1 | 0.146±0.004 | |||||||||||||||||||

| P | 8±0.1 | 0.315±0.004 | |||||||||||||||||||

| F | 7.5±0.1 | 0.295±0.004 | |||||||||||||||||||

| E | 1.75±0.1 | 0.069±0.004 | |||||||||||||||||||

| D | 1.5+0.1/-0.0 | 0.059+0.004/-0.0 | |||||||||||||||||||

| P0 | 4±0.1 | 0.157±0.004 | |||||||||||||||||||

| P2 | 2±0.1 | 0.079±0.004 | |||||||||||||||||||

| T | 0.4±0.1 | 0.016±0.004 | |||||||||||||||||||

| D0 | 13.3±0.15 | 0.524±0.006 | |||||||||||||||||||

| D1 | 330±2 | 12.992±0.079 | |||||||||||||||||||

| D2 | 100+1/-2 | 3.937+0.039/-0.079 | |||||||||||||||||||

| W1 | 16.5±0.4 | 0.65±0.016 | |||||||||||||||||||

Soldering Parameters - Reflow Soldering (Surface Mount Devices)

| Reflow Condition | Pb - Free assembly | |||||||||||||||||||||||

| Pre Heat | -Temperature Min (Ts(min)) | 150°C | ||||||||||||||||||||||

| -Temperature Max (Ts(max)) | 200°C | |||||||||||||||||||||||

| - Time (min to max) (ts) | 60 -180 Seconds | |||||||||||||||||||||||

| Average ramp up rate ( Liquids Temp TL) to peak | 3°C/second max | |||||||||||||||||||||||

| TS(max) to TL - Ramp-up Rate | 5°C/second max | |||||||||||||||||||||||

| Reflow | - Temperature (TL) (Liquids) | 217°C | ||||||||||||||||||||||

| - Time (min to max) (ts) | 60 -150 Seconds | |||||||||||||||||||||||

| Peak Temperature (TP) | 260 +0/-5°C | |||||||||||||||||||||||

| Time within 5°C of actual peak Temperature (tp) | 10 - 30 Seconds | |||||||||||||||||||||||

| Ramp-down Rate | 6°C/second max | |||||||||||||||||||||||

| Time 25°C to peak Temperature (TP) | 8 minutes Max | |||||||||||||||||||||||

| Do not exceed | 260°C | |||||||||||||||||||||||