| Price | Negotiable |

| MOQ | 1000PCS |

| Delivery Time | 5-7 Days |

| Brand | Tian Rui |

| Place of Origin | China |

| Certification | VDE CCC |

| Model Number | RH Series |

| Packaging Details | 100PCS/Bag |

| Payment Terms | D/P, T/T,Paypal, Western Union |

| Supply Ability | 1000000PCS/Month |

| Coated | Resin Coating | Temperature | 75C to 250C |

| Place of Origin | China | Sample | Available |

| Packaging Details | 100PCS/Bag | Fuse Element | Low melting point alloy wire |

| Model Number | RH Series | Supply Ability | 1000000PCS/Month |

| Certification | VDE CCC | Rated Voltage | 250V |

| Case | Ceramic | With | Mounting Hole |

| Brand Name | Tian Rui | Payment Terms | D/P, T/T,Paypal, Western Union |

| Wire Material | High temperature fluorine plastic wire | Packing | PE bag |

| Price | Negotiable | Delivery Time | 5-7 Days |

| Minimum Order Quantity | 1000PCS | Lead | Radial Lead |

| Rated Current | 1A to 20A | Application | Over-heat protection |

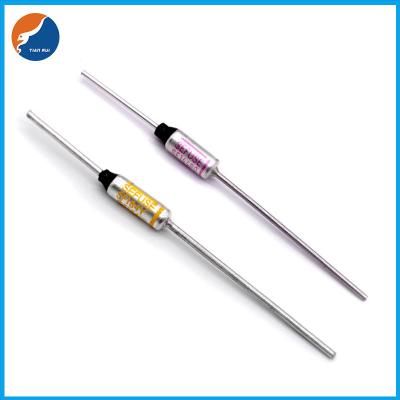

RH Mounting Hole Electric Motor Lead Ceramic Body Temperature Fuse Link Radial Thermal Fuse

Rated current: 1A 2A 3A 5A 10A 15A 20A

Rated voltage: 250V AC

Rated temperature: 75℃ to 150℃

Case: Ceramic

Lead: High temperature fluorine plastic wire, radial

| Product Name | Thermal Fuse | Dimens ions(mm) | APPROVALS | |||||||||||||||||||

| A | B/mm | C | D | ¢Hold diameter | Material | |||||||||||||||||

| Type | RH-02 | 15 | 50x100 0.5 square high temperature fluorine plastic wire |

8 | 3.0 | 4.3 | Plastic | TUV | VDE | CCC | ||||||||||||

| 16 | 9 | 3.5 | 4.5 | Ceramic | ||||||||||||||||||

| 20 | 11 | 4.8 | 5.0 | Plastic | ||||||||||||||||||

| 20 | 12 | 5.0 | 4.5 | Ceramic | ||||||||||||||||||

| Rated operating temperature Tf(℃) | Actual operating temperature Tf(℃) | Holding temperature Tc(℃) | Limit temperature Tm(℃) | Electrical performance | ||||||||||||||||||

| Rated voltage | Rated current | |||||||||||||||||||||

| AC(V) | A | |||||||||||||||||||||

| 75 | 71±3 | 40 | 150 | 250 | 1,2,3 | 5,10 | 15,20 | ○ | ○ | ● | ||||||||||||

| 80 | 75±2 | 45 | 150 | ○ | ○ | ● | ||||||||||||||||

| 85 | 80±2 | 50 | 150 | ○ | ○ | ● | ||||||||||||||||

| 92 | 88±2 | 55 | 150 | ○ | ○ | ● | ||||||||||||||||

| 102 | 97±2 | 65 | 150 | ○ | ○ | ● | ||||||||||||||||

| 105 | 100±2 | 75 | 180 | ○ | ○ | ● | ||||||||||||||||

| 110 | 105±2 | 75 | 180 | ○ | ○ | ● | ||||||||||||||||

| 115 | 110±2 | 80 | 180 | ○ | ● | ● | ||||||||||||||||

| 120 | 115±2 | 80 | 180 | ○ | ○ | ● | ||||||||||||||||

| 125 | 120±2 | 95 | 180 | ○ | ● | ● | ||||||||||||||||

| 130 | 126±1 | 100 | 180 | ○ | ● | ● | ||||||||||||||||

| 135 | 130±1 | 105 | 180 | ○ | ○ | ● | ||||||||||||||||

| 140 | 136±1 | 105 | 180 | ○ | ● | ● | ||||||||||||||||

| 145 | 140±1 | 110 | 180 | ○ | ● | ● | ||||||||||||||||

| 150 | 145±2 | 110 | 180 | ○ | ● | ● | ||||||||||||||||

| 160 | 155±2 | 120 | 180 | ○ | ○ | ● | ||||||||||||||||

| 167 | 160±2 | 136 | 200 | ○ | ○ | ● | ||||||||||||||||

| 170 | 165±1 | 140 | 220 | ○ | ○ | ● | ||||||||||||||||

| 175 | 170±2 | 145 | 220 | ○ | ○ | ● | ||||||||||||||||

| 180 | 175±2 | 145 | 200 | ○ | ○ | ● | ||||||||||||||||

| 185 | 180±2 | 150 | 220 | ○ | ○ | ● | ||||||||||||||||

| 200 | 195±2 | 160 | 230 | ○ | ○ | ● | ||||||||||||||||

| 216 | 210±2 | 180 | 250 | ○ | ○ | ● | ||||||||||||||||

| 220 | 215±2 | 180 | 250 | ○ | ○ | ● | ||||||||||||||||

| 230 | 225±2 | 195 | 250 | ○ | ○ | ● | ||||||||||||||||

| 240 | 235±2 | 205 | 260 | ○ | ○ | ● | ||||||||||||||||

| 250 | 245±2 | 210 | 280 | ○ | ○ | ● | ||||||||||||||||

Structure

Thermal fuse is composed of ceramic shell, low melting point alloy wire, special resin, high temperature fluoroplastic wire and sealing resin.

Apprearance

The marking must be clear; the sealing resin should fill the mouth and it is acceptable; the lead tin-plated layer is good; there is no oxidized black spot damage; the shell has no damage marks, perforations, etc.