| Price | 500 |

| MOQ | 1 |

| Delivery Time | 1-2days |

| Brand | FUJI-CNSMT |

| Place of Origin | Shenzhen,China |

| Certification | CE- FUJI feeder calibration Jig |

| Model Number | FUJI CP6 feeder calibration jig |

| Packaging Details | Standard woodenbox |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 5perday |

| Place of Origin | Shenzhen,China | Warranty | 1YEAR |

| Packaging Details | Standard woodenbox | Product Name | FUJI CP6 feeder calibration jig |

| Material | stee .plastic,metal | Model Number | FUJI CP6 feeder calibration jig |

| Supply Ability | 5perday | Certification | CE- FUJI feeder calibration Jig |

| Weight | 38kg | Brand Name | FUJI-CNSMT |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram | Lead time | 1-2days |

| FEEDER TYPE | FUJI CP6 CP7 FEEDER | Price | 500 |

| Delivery Time | 1-2days | Minimum Order Quantity | 1 |

| Voltage | 110v/220v option | Manufacturer | CNSMT |

| Product Model | FUJI CP6 feeder calibration jig | Application | FUJI CP6 pick and place machine |

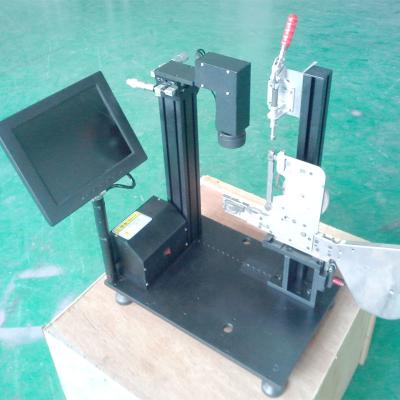

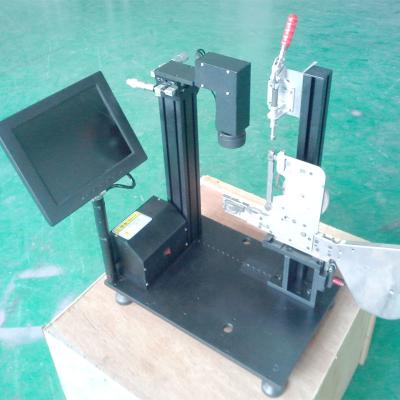

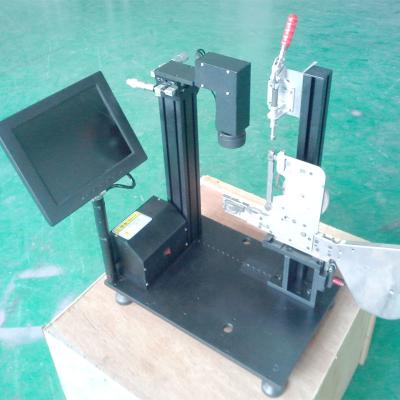

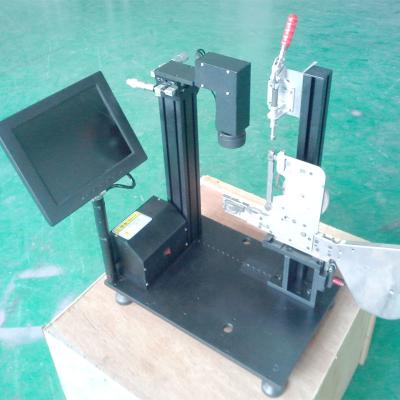

FUJI CP6 CP7 SMT Feeder Calibration Jig Instrument 106 Kpa 250V 50Hz

FUJI CP6 CP7 feeder calibration jig,SMT FEEDER calibration instrument

Product Description

FUJI

CP6

FEEDER

Calibrator

1.

The

structure

of

the

whole

machine

is

simplified,

the

operation

is

simple,

and

the

function

is

optimized.

And

use

high-precision

gears

to

ensure

position

stability

and

greatly

improve

work

efficiency.

2. Accuracy testing. Reclaiming position, height, and pressure bar height can all be accurately measured. Can better grasp the quality status.

3. The use of color LED display, LED lighting, 50 times magnification CCD camera, make the structure more compact and beautiful. Effectively reduce eye fatigue and improve the quality of work.

4. It is easy to operate, and can simulate the placement machine, automatically and continuously observe the picking position, can more clearly grasp the continuous running quality of FEEDER, so as to more effectively control the throwing rate.

Functions

and

features:

1.

X-Y-Z

axis

adjustment;

2.

Axis

camera

that

can

be

adjusted

directly;

3.

Built-in

220V

DC

power

supply;

4.

Cross

cursor

with

scale;

5.

Auto

and

step

function;

6.

LED

display;

7.

Feeder

control

fixture;

8.

8*2mm/12*4mm/16*8mm

and

24*8mm

feeder

control

belt.

Purpose: FEEDER calibration instrument is used to calibrate the model FEEDER

2.

Product

specifications

2-1.

Equipment

main

parameters:

2-1-1. Input power: AC220V (50HZ),

2-1-2. Rated power: 45 W

2-1-3. Supply equipment air pressure: 0.5MPa(=5bar)

2-1-4. Overall dimensions (body size): length×width×height=450mm×300mm×540mm

2-1-5. Equipment weight (excluding monitor): 28Kg

2-1-6.

Adjustable

stroke

of

the

transmission

part:

X

direction:

37±0.5mm

Y

direction:

37±0.5mm

2-2.

Component

parameters:

2-2-1.

CCD

camera:

Parameter

index

data

Color

CCD

size

1/4

inch

Resolution

400TVL

Signal

system

PAL

Minimum

illumination

(F1.2)

≤1.5Lux

Lens

interface

C/CS

Working

voltage

DC

12V

Working

temperature

-10℃~+50℃

Working

environment

Humidity:

40%~95%,

atmospheric

pressure:

86Kpa~106

Kpa

2-2-2. Magnifying lens:

Telecentric

lens,

adjustable

distance

10MM---800MM

2-2-3.

Color

liquid

crystal

display:

Power

source:

AC:

180~250V

50Hz

Power

consumption:

15W

Video

input:

0.7~1.4Vpp,

75Ω

Case

structure:

plastic

case,

LCD

panel

Colour:

Black

Horizontal

center

definition:

≥800TVL

Dimensions:

300

(W)

×

300

(H)

×

100

(D)

Weight:

38Kg

2-2-4.

Work

lights:

Working

voltage:

DC

12V

Rated

power

consumption:

10W

2-3.

Working

environment

conditions:

Temperature:

+10℃~+35℃

Humidity:

below

50%

(35℃)

below

90%

(20℃)

Surrounding

environment:

There

should

be

no

corrosive

gas.

3.

How

to

use

the

product

3-1.

Preparation

before

inspection

*

Please

install

the

monitor

and

connect

it

to

a

220v

power

supply.

Use

a

video

signal

cable

to

connect

the

CCD

output

terminal

to

the

video

signal

input

interface

of

the

monitor.

*

Connect

the

DC

plug

cable

to

the

power

input

jack

of

the

CCD

camera.

*

Connect

the

power

supply

of

the

electrical

control

box

to

the

220v

power

supply.

*

First

turn

on

the

switch

on

the

back

of

the

electrical

control

box

and

the

power

switch

of

the

display.

At

this

time,

there

will

be

a

cross

scale

cursor

displayed

on

the

display;

if

it

is

not

displayed,

please

check

whether

the

power

supply

and

signal

wires

are

correct.

Adjust

the

brightness

and

contrast

of

the

display

until

the

display

is

clear.

*

Install

the

calibration

ruler

on

a

FEEDER

with

the

best

placement

rate

in

production,

install

the

FEEDER

on

the

placement

platform,

and

fix

it.

*

Cycle/Stop

button:

Press

the

Cycle/Stop

button

once,

and

the

motor

will

drive

the

feeder

one

step

forward.

Keep

pressing

the

Cycle/Stop

button,

and

the

machine

will

automatically

drive

the

motor

to

drive

the

feeder

forward

until

the

button

is

released.

*

Auto/Manual

key:

Press

the

Auto/Manual

key

once,

the

display

light

is

on,

press

the

Cycle/Stop

key

once

to

drive

the

motor

to

continuously

drive

the

feeder

forward.

Press

the

Cycle/Stop

key

again,

and

the

drive

motor

will

pause.

*

Speed

control

key:

Adjust

the

Speed

control

switch,

and

the

speed

of

driving

the

motor

will

change

accordingly.

3-2.

Measurement

method

Rotate

the

adjustment

knobs

in

the

X,

Y,

and

Z

directions

to

move

the

cross

cursor

in

the

display

to

the

center

of

the

suction

position

of

the

standard

feeder,

and

make

it

consistent

with

the

center

of

the

cross

scale

cursor.

Use

the

cross

scale

cursor

as

a

reference

to

determine

the

to-be-calibrated

Feeder

feed

interval

position.

3-3.

Adjustment

of

feeder

If

necessary,

make

the

following

adjustments.

(1)

Adjustment

of

interval

position

in

X

direction

(2) Confirm

① Confirm the interval position

② Confirmation of the position of the shutter

3-3-1. Adjustment of interval position in X direction

(1)

First

use

the

standard

feeder

to

determine

the

correct

feeding

interval

position,

(2)

Install

the

calibration

ruler

on

the

feeder

to

be

adjusted.

Note:

The

calibration

ruler

should

be

measured

from

a

position

about

30mm

away

from

the

front

hole.

(3)

Please

remove

the

end

cover

of

the

feeder

that

needs

to

be

adjusted

(as

shown

in

Figure

1),

and

then

install

it

on

the

base

of

the

feeder.

(4)

Slightly

loosen

the

fixing

screw

of

the

worm

gear.

(5)

Rotate

the

motor

shaft,

clamp

the

anti-rotation

device

on

the

shaft

to

the

body

card

position,

and

press

it

with

your

fingers.

At

this

time,

the

motor

shaft

does

not

move.

Rotate

and

adjust

the

worm

gear

rod,

the

worm

gear

drives

the

big

gear

to

adjust

the

feeding

position

to

the

correct

position,

so

that

the

interval

position

of

the

correction

ruler

is

adjusted

Align

the

hole

with

the

center

of

the

cross

cursor

in

the

display,

and

then

tighten

the

worm

gear

fixing

screw.

(6)

Load

and

unload

the

feeder

twice,

confirm

that

the

interval

position

has

not

changed,

(7)

Press

the

forward

button

on

the

feeder

several

times

to

confirm

whether

the

feeding

position

is

correct.

3-3-2.

Confirm

(1)

Confirm

the

interval

position

After

adjustment,

confirm

the

interval

position

on

the

fixture

body,

if

the

position

is

skewed,

please

re-adjust

it.

Note:

When

confirming

the

interval

position,

please

press

the

"inching"

key

while

selecting

the

position

to

confirm.

In

addition,

load

and

unload

the

tape

feeder

3

times,

Confirm

the

location

repeatedly.

(2)

Confirm

the

position

of

the

shutter

On

the

feeder

base,

confirm

the

center

of

the

shutter

in

the

X

direction

Whether

the

heart

is

in

the

center

of

the

cross

cursor

in

the

microscope.

If

the

position

is

too

skewed,

replace

the

upper

guard.

4.

Maintenance

4-1.

Daily

inspection

(1)

Please

check

the

contact

surface

of

the

feeder

and

the

feeder

base

for

bumps

and

foreign

objects

(dirt,

etc.)

caused

by

the

collision.

(2) Please use your eyes to check whether the correction ruler is bent, and check whether the sprocket bite hole is worn or not.

(3) The feeder calibration instrument needs to be kept clean. Do not bump the feeder against the body of the machine during debugging. The surface should be wiped after each use. The feeder base should be added with a proper amount of lubricating oil. After the calibration ruler is used up, its integrity should be ensured to avoid deformation and affect accuracy.

(4) After using the calibrator, if you do not use it for a long time, please cover the magnifying lens cover to prevent the lens from getting dirty and damaged.

| samsung feeder calibration jig |

| siplace feeder calibration jig |

| smd feeder calibration jig |

| smd tape feeder calibration jig |

| smt feeder parts calibration jig |

| smt feeder types calibration jig |

| yamaha cl feeder calibration jig |

| yamaha feeder calibration jig |

How can i buy machine from you ?

(1) Consult us on line or by e-mail

(2) Negotiate and confirm the final price , shipping , payment method and other terms

(3) Send you the perfroma invoice and confirm your order

(4) Make the payment according to the method put on proforma nvoice

(5) We prepare your order in terms of the proforma invoice after confirming your full payment . And 100% quality check before shipping

(6) Send your order via express or by air or by sea .

Packing & Delivery

Certification

Company Information

CNSMT

is

the

leading

manufacturer

and

supplieir

for

SMT

machines

and

Solution

with

over

10

years'

experience

in

China.

And

we

can

also

do

OEM&ODM

for

SMT

traders,

we

have

vast

of

sources

in

SMT

field,even

you

need

used

or

new

SMT

equipments

or

other

parts,

we

can

help

you

get

the

best

quality

and

competitive

cost

machines.

What

we

can

do

for

you:

※

We

have

our

own

factory

make

SMT

equipments

and

devices

※

We

have

a

professional

technich

engineer

team

for

produce

machines

※ We can customize variety of SMT machines for you according your requirements

※ We buy and sell used and new SMT equipments all over the world

※

We

provide

you

SMT

full

line

machines

and

export

to

worldwide

※

Becoming

the

most

reliable

Chinese

partner

for

you.

FAQ:

1. Are you factory?

Yes, we are factory supplier focus SMT machines and devices for 14 years.

2. Can you email the catalog?

Yes, we can send you by email with whole catalog.

3. How to order online?

Confirm

product

(quantity,

price,

payment,

shipping

etc)---waiting

for

email

---confirm

order---make

initial

payment---production

finish---make

balance

payment---shipping

*

click

to

learn

about

trade

assurance

4.

What

about

the

payment

way?

100%T/T

advance

or

30%

deposit,

balance

paid

before

delivery

--

amount

>

USD5,000

100%

deposit

--

amount

<

USD5,000

5.

What's

the

shipping

way

and

timing?

We will ship the machine by DHL,Fedex, UPS,etc (Door to Door Service), around 5 days to arrive.

Or by Air to your airport (Door to Airport Service ), around 3 days to arrive.

Or by Sea to the seaport, Minium CBM requirement : 1 CBM, around 30days to arrive.

6. What's the warranty item?

1 year warranty free for spare parts, Whole life technicial support.

We have professional after sales team, if any question, assistant videos are also provided in after-sale service.