| Price | Negotiable |

| MOQ | 1 SET |

| Delivery Time | Negotiable |

| Brand | CHASING |

| Place of Origin | Shanghai |

| Certification | CE |

| Model Number | SZL |

| Packaging Details | Ply-wooden box |

| Payment Terms | T/T, L/C |

| Supply Ability | 35sets/month |

| Homogenizer speed | 0-3600 rpm | Place of Origin | Shanghai |

| Machine Function | Mixer, homogenizer, heating, cooling, vacuum | Packaging Details | Ply-wooden box |

| Material | 316L | Model Number | SZL |

| Supply Ability | 35sets/month | Certification | CE |

| Brand Name | CHASING | Payment Terms | T/T, L/C |

| Type | New | Price | Negotiable |

| Heating | By steam or electric | Minimum Order Quantity | 1 SET |

| Voltage | Customization | Application | Cosmetic product |

Brief Description

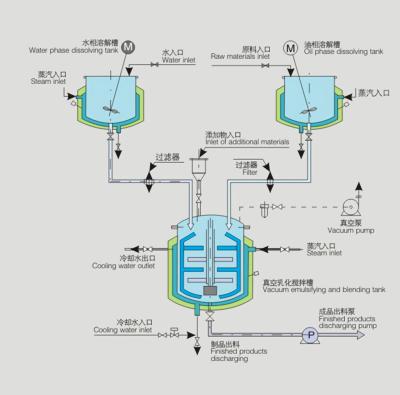

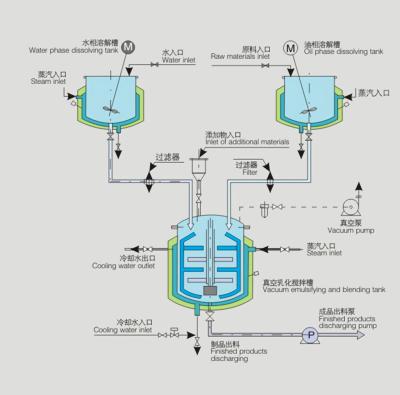

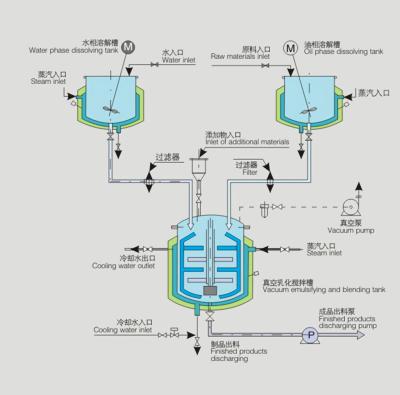

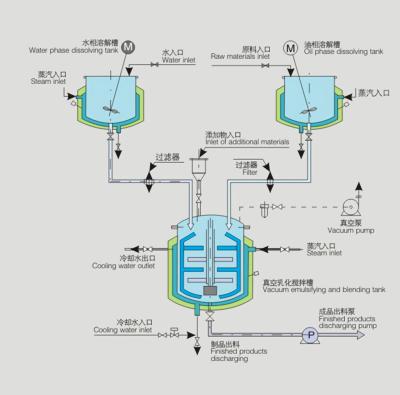

The machine is suitable for dispersing, emulsifying, homogenizing and blending materials in combination with high shear emulsifiers. Optional feeding system, unloading system, temperature control system, vacuum system, PH online measurement and control system, CIP system, etc., are widely used and have strong controllability. It can also be customized as a sanitary grade for production and pilot trials in the pharmaceutical, food and cosmetic industries.

Homogeneous

emulsification

technology

and

solutions

from

Germany

are

specially

designed

for

refined

and

homogeneous

products.

It

can

be

equipped

with

a

variety

of

agitators

such

as

wall

scraping

or

spiral

ribbons

to

easily

handle

materials

with

a

viscosity

of

1-300,000CP.

Real-time

measurement/control

components,

temperature,

pressure,

PH

value

and

other

parameters

can

be

easily

controlled

in

your

hands.

Basic Parameter

| Main pot | Water pot | Oil pot | Hydraulic lifting | |||||

| Working volume |

Homogenizer Power |

Slow mixer power | Vacuum pump power |

Working volume

|

Mixer power |

Working volume

|

Mixer power |

|

| 10L | 1.1kw | 0.8kw | 0.75kw | 8L | 0.18kw | 5L | 0.18kw | 0.75kw |

| 50L | 4-5.5kw | 0.75kw | 0.75kw | 40L | 0.2kw | 25L | 0.2kw | 0.75kw |

| 100L | 5.5-7.5kw | 1.5kw | 1.5kw | 80L | 1.1kw | 50L | 1.1kw | 1.5kw |

| 200L | 7.5-11kw | 2.2kw | 2.2kw | 160L | 1.5kw | 100L | 1.5kw | 1.5kw |

| 300L | 11-15kw | 3kw | 2.2kw | 240L | 1.5-2.2kw | 150L | 1.5-2.2kw | 1.5kw |

| 500L | 15-18.5kw | 5.5kw | 2.2kw | 400L | 3-4kw | 250L | 3-4kw | 2.2kw |

| 1000L | 18.5kw | 7.5kw | 3-4kw | 800L | 4-5.5kw | 500L | 4-5.5kw | 2.2kw |

Features

Basic function

Material: All the parts may contact with the material are using sanitary SS316L and the jacket and outside layer using SS304. The whole structure is triple jacket and cooling or heating carry out within the same jacket. There is a insulation on the outside to protect the worker from being scalded and to ensure the producing security. The production comply with the requirements of GMP.

Polishing: The inside and outside of the pot are mirror-polished and easy-clean without remain.

Low Blending speed of main pot: 10-63 rpm

Homogenizing speed of main pot:100-3600rpm

Blending speed of Oil/Water pot:10-1440rpm or 960rpm

Electric Power: 380V,50/60Hz (customize according to customer’s request)