| Price | Negotiated The Price |

| MOQ | 500 |

| Delivery Time | 10-12 working days |

| Brand | SECORE |

| Place of Origin | Guangdong |

| Certification | ISO9901 |

| Model Number | BLS-3625I |

| Packaging Details | 50pcs per carton or as request |

| Payment Terms | T/T, D/A |

| Supply Ability | 100000pcs per month |

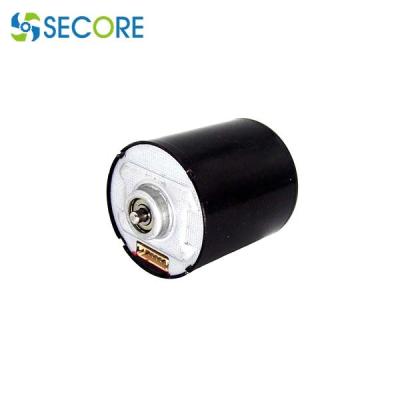

| commutating | brushless, EC | Construction | Permanent magnet |

| Place of Origin | Guangdong | Packaging Details | 50pcs per carton or as request |

| No-load Speed | 4600RPM or customized | Rated speed | 3900rpm or as per request |

| Motor dimension | Φ36*25(mm)diameter*length | Model Number | BLS-3625I |

| Supply Ability | 100000pcs per month | Certification | ISO9901 |

| Brand Name | SECORE | Payment Terms | T/T, D/A |

| Price | Negotiated The Price | Delivery Time | 10-12 working days |

| Rated voltage | 12V | Minimum Order Quantity | 500 |

| Rated Torque | 100g.cm | Typical usage | mixer, smart window, electric lock |

Mixer

Bldc

Motor

48V

3

Phases

Dc

Brushless

Motors

D36mm

For

Medical

Device

Performance

and

features

Of

Miniature

inner

rotor

bldc

motor

1.

Multiple

voltage

option:

3~48V,

310V

2.

Multiple

speed

options:

5-100000rpm

3.

Torque:

0.05kg.cm~600kg.cm

4.

Shaft:

D

shape,

dual-D,

key

slot,

knurled,

screw,

hobbing,

shaft

hole,

shaft

pin

5.

Commutation:

brush,

brushless

6.

Application: Breeding

Shed,

Thermal

insulation

greenhouse,

Vegetable

greenhouse,

Flower

greenhouse,

Planting

greenhouses,

Aquaculture

greenhouse

etc

7.

Equipment:

gearbox,

drive,

brake,

encoder,

fan

etc

| MODEL | VOLTAGE | NO LOAD | AT MAXIMUM EFFICIENCY | STALL | ||||

|

SPEED RPM |

CURRENT A |

SPEED RPM |

TORQUE gf.cm |

CURRENT A |

TORQUE gf.cm |

CURRENT A |

||

| BLS-2847I | 24 | 3700 | 0.08 | 2800 | 200 | 0.65 | 820 | 1.6 |

| BLS-2847I | 32 | 20500 | 0.14 | 18050 | 200 | 1.3 | 1000 | 5.1 |

Motor

dimensions

Performance

curve

Typical

Application

Advantages

and

shortages of

BLDC

Motors:

Advantages:

1.The

speed

of

the

brushless

DC

motor

is

higher

than

that

of

the

brushed

DC

motor

(the

maximum

speed

is

100,000

rpm

vs.

10,000

rpm).

2.

Longer

service

life

(over

10,000

hours)

3.

More

reliable

and

efficient.

4.

With

the

exception

of

bearings,

there

are

no

wearing

parts,

and

maintenance

operations

are

less.

In

fact,

BLDC

motors

can

run

at

very

high

RPMs,

making

them

ideal

for

applications

that

require

high

RPMs,

such

as

hair

dryers,

wall

breakers,

fans,

grinders

or

saws.

The

brushless

DC

motor

is

systematically

equipped

with

drivers,

encoders

and

sensors,

which

can

feedback

information

data

such

as

speed

and

torque

to

achieve

precise

control.

Therefore,

they

are

especially

suitable

for

precision

applications

that

require

precise

control,

such

as

medical

instruments,

aerospace

equipment,

servo

robots,

etc.

Shortcoming:

a)

High

initial

cost:

Each

BLDC

motor

requires

an

electronically

commutated

drive,

which

is

expensive.

b)

Brushless

DC

motors

often

also

require

gear

reducers

in

drive

applications.