| Price | Negotiable price |

| MOQ | 1PCS |

| Delivery Time | 2-5days |

| Brand | Belparts |

| Place of Origin | China |

| Model Number | ZX330-1 John Deere 270CLC |

| Packaging Details | Wooden packing |

| Payment Terms | T/T, Paypal and Trade Assurance |

| Supply Ability | 1000pieces |

| Condition | new | Place of Origin | China |

| Warranty | 1 Year | Packaging Details | Wooden packing |

| Color | According to customer requirement | Model Number | ZX330-1 John Deere 270CLC |

| Supply Ability | 1000pieces | Part Name | travel motor |

| Brand Name | Belparts | Payment Terms | T/T, Paypal and Trade Assurance |

| Price | Negotiable price | Delivery Time | 2-5days |

| Quality | Made In China | Minimum Order Quantity | 1PCS |

| Model | ZX330-1 John Deere 270CLC | Application | Excavator, Engineering machinery equipment |

| Power | Hydraulic |

Belparts excavator spare parts John Deere 270CLC Hitachi Final drive ZX330-1.

If you are interested in any models, please tell us the OEM model code, and we can check the prices for you very soon.

More detail please contact with us!

Other

models

also

available:

Main product

Reputation

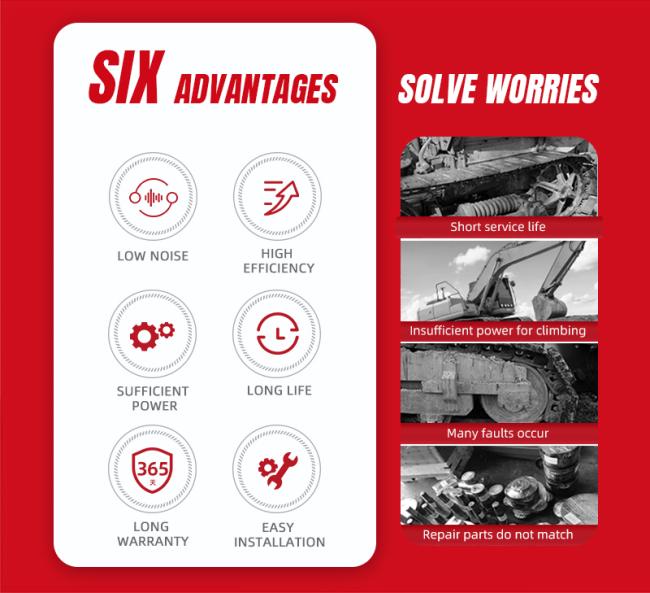

Why can our excavator equipment work even in harsh environments?

1. Durability and reliability

Reinforced structural design: using high-strength steel and sturdy welded structure, capable of withstanding extreme temperature differences, heavy load operations, and complex terrain tests.

Sealing technology: The hydraulic system and key components adopt advanced sealing to prevent dust, mud, and moisture from entering, ensuring long-term stable operation.

2. Adapt to various harsh environments

High temperature or cold environment: equipped with professional cooling system and low-temperature start function, ensuring reliable operation in desert high temperature or polar low temperature.

Adaptability to harsh terrain: The track design and efficient chassis suspension system can cope with complex terrains such as mud, mountains, and swamps.

3. Low maintenance cost

Long life components: Introducing wear-resistant materials and efficient lubrication systems to extend the replacement cycle of vulnerable parts.

Intelligent diagnostic system: Real time monitoring of equipment operation status, early warning of potential faults, and reduction of sudden downtime rate.

Easy to maintain design: Reasonable arrangement of key components, convenient maintenance, and reduced repair time and labor costs.

Main product

| EC480D | 14631200 | Travel gearbox |

| EC480D EC480E | 14733880 ,14632579 | final drive |

| E323E | 507-6558 | Travel gearbox |

| E320 | 215-9982 | TRAVEL MOTOR САТ320, 325 |

| E330GC | 568-2306 | TRAVEL MOTOR САТ330GC |

| Solar420 | 401-00004 | TRAVEL MOTOR Solar 420 |

| R320-7 | 31N9-40030 | TRAVEL MOTOR ASSY R320-7 |

| PC300-8MO | 207-27-00590 | Travel motor PC300-8MO |

| ZX120-3/6 | 9180731 | TRAVEL MOTOR ASSY HITACHI ZX120-3 CH |

| ZX270-3 ZX330-1 | 9255876 | TRAVEL MOTOR HITACHI ZX270-3 ZX330-1 CH |

| SК250-6Е | LQ15V00019F LQ15V00007F1 | TRAVEL GEAR BOX SК250-6Е CH |

| EC300 | 14265276 | TRAVEL MOTOR ASSY VOLVO EС300 |

| ZX350H-5A | 9281920 | TRAVEL GEAR BOX HITACHI ZX350H-5A |

| SK350LC-10 | LC53D00027F1 (LC53D00027F2) | Travel motor |

| JD350G ZX350-3 | 9281921 | Final drive assy |

| CX210 CX240 | KRA1426 | Final drive assy |

| E345D | 227-6045 | Travel gearbox |

| ZX870-3 | 9219275 | Travel gearbox |

| ZX670-3 | 9254462 | Travel gearbox |

Exhibition Strength

In the past few years, in order to sell our products all over the world, we have participated in many exhibitions, such as Beijing Construction Machinery Exhibition in 2017, Shanghai Bauma Exhibition in 2018, German Exhibition in 2019, and we will continue to participate in various exhibitions in the future to let our products go to the world.

Company information

GZ

Yuexiang

Engineering

Machinery

Co.,

Ltd,

founded

in

September

2013,

is

a

foreign

trade

company,

which

is

specialized

in

procuring

and

selling

excavator

parts.Our

main

products

are

excavator

hydraulic

After sales guarantee service

1.quick response

Provide a 24-hour service hotline to promptly respond to customer needs and ensure quick resolution of issues.

2.Professional maintenance

Equipped with a professional technical team, providing on-site service, and using original accessories to ensure equipment performance.

3.Regular maintenance

Provide regular maintenance plans to extend equipment lifespan and improve work efficiency.

4.technical support

Provide operational training and technical consultation to help customers better use the equipment.