| Price | USD20000-USD300000 |

| MOQ | 1set |

| Delivery Time | 60-90days |

| Brand | JingSu ShengMan |

| Place of Origin | China |

| Certification | CE and ISO9001 |

| Model Number | WFJ |

| Packaging Details | Plywood Cases |

| Payment Terms | L/C, T/T |

| Supply Ability | 10sets |

| Condition | New | Place of Origin | China |

| Warranty | 1 year | Machine Type | grinder |

| Packaging Details | Plywood Cases | Standard | GMP |

| Material | stainless steel | Model Number | WFJ |

| Supply Ability | 10sets | Certification | CE and ISO9001 |

| Brand Name | JingSu ShengMan | Payment Terms | L/C, T/T |

| application | pharmaceutical, food, chemical | Price | USD20000-USD300000 |

| Delivery Time | 60-90days | Heating System | Steam,Electronic,oil |

| Minimum Order Quantity | 1set | Voltage | Customized |

| power | 4-15kw | dimension | requirement from customer |

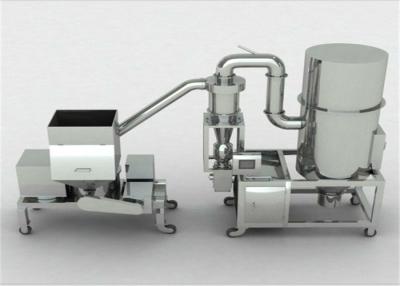

Dry vegetable grinder mushroom powder making machine super fine grinding pulverizer

1. The design is compact and structure reasonable. The machine is equipped with an internal classification mechanism so that grinding and classification are carried out simultaneously, thus reducing energy consumption.

2. Euipped with a draught fan, which dissipates the heat in the machine continuously, the machine is fit for the grinding of thermal sensitive materials.

3. Having a great adaptability and narrow granularity distribution. The granularity of the product is even and fineness may reach 80-320 mesh.

4. Regulate the speed of the classifier or amount the air without stopping the machine and evenly distributed products of the required granularity will be obtained.

5. The top cover of the main machine is opened with pneumatic springs and the body is contructed in such a way that it may be opened to two sides so that no hindrance will be met in cleaning and servicing the internal parts.

6. The main grinding parts are made of high-grade alloy tool steel so that the service life or change cycle of the wear parts is greatly lengthened.

7. High-speed precision bearings imported from abroad are adopted for the bearing system so that the whole machine runs smoothly with little vibration and noise.

8. The pipes are of quick – detachment construction, making detachment and cleaning quick and convenient.

9. Equipped with a cyclone separator and a collector , so there is no powder flying during production. The dust collecting bag can effectively collect the fine powder in the air current so as to meet the requirements for cleanness and environmental protection in waste gas discharge.

10. The fine powder collected by the dust collecting bag can be effectively recycled. Thus the material loss is reduced.

Technical Parameters

Note: because the raw material exist in difference, the output in the table is for reference only

Technical advantages

1

In

the

machine

chamber,

there

is

the

leaf

structure.

When

operation,

the

air

in

the

grinding

chamber

is

blown

out

by

the

rotary

leaves

taking

out

the

heat.

Therefore,

there

is

no

much

heat

in

the

chamber

to

ensure

the

characteristic

of

the

material.

2

When

operation,

the

strong

air

flow

can

expel

the

material

out.

So

it

can

pulverized

the

heat

sensitive

and

sticky

material

with

good

effect.

3.

For

the

good

performance

on

the

heat,

it

can

be

the

substitute

of

universal

crusher.

4.

Expect

the

pull

force

of

the

fan,

the

air

flow

in

the

grinding

chamber

blows

the

fine

powder

out

(the

fineness

of

the

powder

is

adjustable

through

the

sieves).

Thus,

it

can

increase

the

capacity

of

the

machine.

Principle

Materials are transported into smashing mesh via screw conveyor, then crushed by the high-speed revolving razor blade. With the negative pressure, materials will be transported into cyclone separator, ejected by pass-breezing machine. Without the powder float in whole producion line the powder float in the sky.

Pre-service:

As

a

good

and

rich

experience

supplier,

we

should

offer

customer

the

best

quality

and

best

price

of

the

machine.

1.

Introduce

the

suitable

product

to

the

customer

in

detail,

answer

the

question

raised

by

customer

carefully.

2.

Make

the

suitabe

project

as

the

customer

requirement

and

make

sure

the

machine

is

suitable

for

the

material.

Sale

service:

(1).

Ensure

product

with

high

quality

and

pre-commissioning

before

delivery.

(2).

Delivery

on

time.

(3).

Provide

full

set

of

documents

as

customer’s

requirements.

After-sale

service:

Provide

considerate

services

to

minimize

clients’

worries.

1.

Assist

clients

to

prepare

for

the

first

construction

scheme.

2.

Install

and

debug

the

equipment.

3.

Train

the

first-line

operators.

4.

Examine

the

equipment.

5.

Take

initiative

to

eliminate

the

troubles

rapidly.

6.

Provide

technical

support.

7.

Establish

long-term

and

friendly

relationship.

Service

commitment:

1.

Provide

clients

one-year

warranty

to

make

sure

the

machine

work

well.

2. We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely.

3. Send every client a preferential quotation.

Jiangsu Shengman Drying Equipment Engineering Co.,Ltd, established in 2011, known as a local leading high-tech enterprise, is located in Zhenglu town, Changzhou, Jiangsu, China. Shengman is a large-scale production enterprise in China drying industry with a registered capital of 35,000,000 RMB, specialized in designing &manufacturing various kinds of dryers, granulators, mixers, grinders ,dust removers, etc. Shengman owns an area of over 200,000㎡, and realizes annual sales of over 70,000,000RMB for consecutive years. Shengman has passed European Union CE authentication, ISO 9001 quality management system certification and got good bank credit for AAA. Now Shengman has been one of the largest drying equipment production enterprises in East China and keeping leading the drying industry’s development.