Diamond

Profile

75x150mm

Welded

Razor

Wire

Mesh

Fence

Support

Customization

|

Attribute

|

Value

|

|

Product

Name

|

Diamond

Profile

75x150mm

Welded

Razor

Wire

Mesh

Fence

Support

Customization

|

|

Razor

Type

|

BTO-22,

BTO-30

|

|

Mesh

Size

|

75x150mm

|

|

International

Standard

|

ASTM,

ISO

|

|

Packaging

|

in

rolls

or

in

pieces

|

|

Application

|

used

as

High

Security

Area

Protection,

Private

Garden,

Barrier

Fence,

etc.

|

Welded

razor

wire

mesh

is

a

multi-functional,

high

security

mesh

fencing

made

of

straight-blade

netting

welded

together,

packaging

into

a

roll

form

for

transport.

Welded

Razor

Wire

Mesh

is

used

in

operations

to

pave

the

field

after

the

installation

of

a

blade

barrier.

This

product

can

protect

you

and

your

property,

and

ensures

the

safety

of

the

protective

barriers.

This

welded

razor

wire

mesh

security

fence

product

is

almost

impossible

to

climb

or

cut

off

with

the

standard

tools,

also

it

has

a

neat

appearance.

Welded

razor

wire

mesh

is

installed

in

various

parts

of

the

world's

airports,

military

bases,

water

substation,

the

border

fence,

oil

depots,

factories

and

so

on.

The

common

Razor

Wire

we

usually

see

is

in

spiral

roll

type.

They

are

often

used

on

top

of

walls,

or

on

top

of

fences,

for

extra

protection.

However,

there

is

another

way

to

use

the

Razor

Wire,

which

is

to

straighten

it

and

cut

them

into

pieces,

and

then

weld

the

straight

razor

pieces

into

a

mesh

panel

shape.

Features

and

Benefits

-

It

is

almost

impossible

to

climb.

-

Sharp

razor

is

a

warning

to

anyone

who

wants

to

break

in.

-

High-strength

steel

core

very

difficult

to

cut

off.

-

Powerful

security

fence

barriers

neat

appearance.

-

No

secondary

use,

so

he

will

not

be

stolen.

-

Extremely

simple

to

install,

needs

three

to

four

to

install

molding.

Raw

Materials

1)

Blade

-

Material:

Galvanized

Steel

or

Stainless

Steel

-

Thickness:

0.5mm

-

Barb

Length:

12-65mm

-

Barb

Spacing:

26-100mm

2)

Core

Wire

-

Material:

Electro

Galvanized

Wire,

Hot-dipped

Galvanized

Wire,

Stainless

Steel

Wire

-

Wire

Diameter:

2.5mm

3)

PVC

Coating

Razor

Barbed

Wire

can

also

be

coated

by

PVC,

so

that

it

has

higher

corrosion

resistance

and

is

more

beautiful.

Green

color

is

commonly

used,

and

other

colors

can

be

customized

according

to

customers'

requirements.

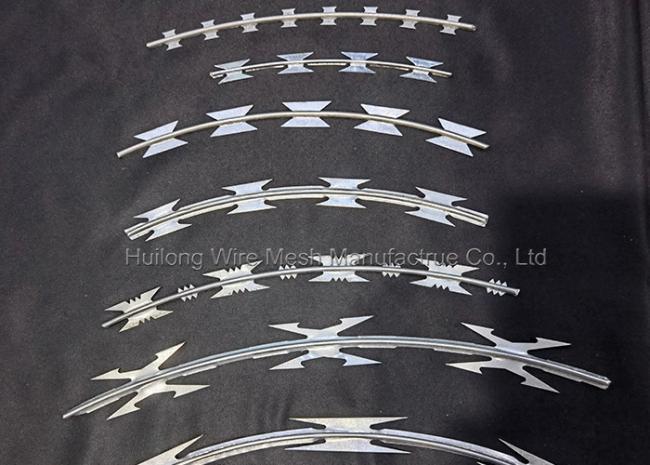

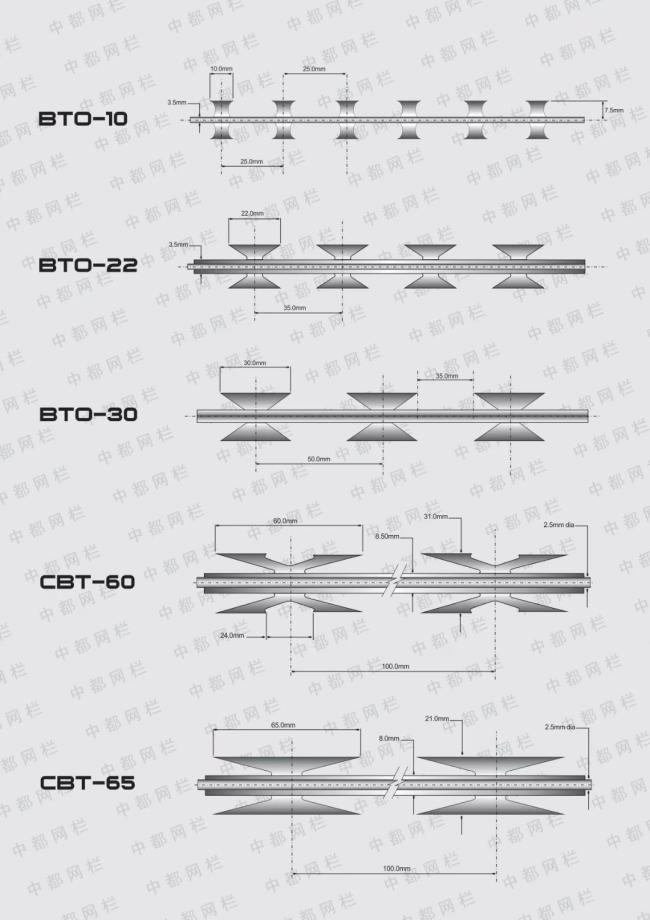

Common

Blade

Types

-

BTO

(Barbed

Tape

Obstacle):

BTO-10,

BTO-22,

BTO-30

-

CBT

(Concertina

Barbed

Tape):

CBT-60,

CBT-65

Mass

Production

Procedure

-

Raw

Material

----

Ready

Razor

Wire

Coils

-

Machine

Straightening

and

Cutting

----

The

coiled

razor

wires

are

straightened

and

cutted

into

pieces

-

Machine

Welding

----

Weld

the

razor

wire

pieces

into

mesh

panel

-

Machine

Rolling

----

It

will

be

made

into

rolls

according

to

customized

length

-

We

can

also

make

it

directly

into

panel

pieces.

-

Packaging

----

In

rolls

or

in

pieces,

with

or

without

pallet.

Special

requirements

can

be

customized.

Quality

Control

System

Quality

management

is

a

part

we

consider

very

important,

because

it

directly

determines

whether

the

customer

is

satisfied

or

not.

From

raw

material

storage,

machine

maintenance,

workers'

qualifications,

technical

standards,

production

process,

to

product

inspection,

packaging

and

transportation,

we

ensure

quality

control

to

meet

customers'

requirements

at

the

most

economical

level.

At

the

same

time,

we

have

a

perfect

after-sales

service

system,

efficient

for

you

to

solve

any

problems

in

the

process

of

order.

International

Standard

for

Razor

Barbed

Wire

ASTM

F1910-98(2018)---Standard

Specification

for

Long

Barbed

Tape

Obstacles

ASTM

F1379-95(2018)---Standard

Terminology

Relating

to

Barbed

Tape

ASTM

F1911-05(2019)---Standard

Practice

for

Installation

of

Barbed

Tape

Quality

Inspection

Before

Loading

Perfect

quality

control

system,

can

ensure

the

delivery

of

goods

on

time.

After

completing

the

mass

production,

quality

inspectors

of

our

factory

and

the

inspectors

designated

by

the

customers

will

check

and

test

the

products

to

ensure

that

the

quality

and

quantity

meet

customers'

requirements.

Meanwhile,

the

inspection

and

loading

process

will

be

timely

fed

back

to

the

customers

in

the

form

of

documents.

After-Sales

Service

System

-

After

the

order

is

confirmed,

we

will

update

the

production

schedule

of

the

goods

in

time.

-

Any

problems

arising

from

our

cooperation

shall

be

answered

within

24

hours

and

solved

within

72

hours.

-

If

any

quality

problem

is

found

before

delivery,

we

will

deal

with

it

in

time.

-

When

the

goods

arrive

at

the

destination

port,

the

customer

finds

the

problem

after

unpacking

the

box.

Please

take

photos

and

feedback

to

us.

We

will

solve

the

problem

within

24

hours.

Frequently

Asked

Questions

Q1:

Are

you

a

factory

or

trading

company?

We

are

a

18-year

factory

and

we

have

registered

trading

company

for

sourcing

more

valuable

products

for

the

customers.

Therefore,

we

have

both

the

advantages

of

factory

and

trading

company.

We

have

our

own

factory,

so

we

can

control

the

product

quality

timely

and

efficiently.

At

the

same

time,

we

also

have

a

professional

international

trade

team,

providing

good

and

professional

services

for

customers.

Q2:

What's

the

MOQ?

MOQ

is

50

coils

for

common

standardized

products

and

ready

stock;

For

Customized

Products,

MOQ

should

be

negotiated

in

advance.

There

is

no

MOQ

for

sample

orders.

Q3:

How

to

guarantee

the

quality

of

products?

We

have

established

the

Department

of

Quality

Assurance,

every

steps

from

raw

material

preparation

to

final

product,

we

have

strict

quality

inspection

system

to

ensure

the

products

meet

international

standards

and

satisfy

customers.

We

resolutely

put

an

end

to

unqualified

products

flowing

into

the

market.

At

the

same

time,

we

will

provide

necessary

follow-up

service

assurance.

Any

problems

arising

from

the

cooperation

shall

be

answered

within

24

hours

and

solved

within

72

hours.

HUILONG

History

-

In

1989,

HUILONG

company

was

established,

the

original

store

was

located

in

Anping

Wire

Mesh

World

Supermarket;

-

In

1994,

Anping

HUILONG

wire

mesh

factory

was

founded,

located

in

Nanhuan

East

Road,

mainly

for

the

domestic

market

and

produce

Welded

Wire

Mesh

Roll,

Welded

Wire

Mesh

Panel,

and

Wire

Mesh

Fence,

etc.;

-

In

1998,

ethnic

Chinese

from

Philippines

visited

us

and

confirmed

the

intention

of

cooperation;

-

In

2004,

Philippines

invested

1

million

funds,

HUILONG

Wire

Mesh

became

a

joint

venture

company

named

as

"ANPING

HUILONG

WIRE

MESH

MANUFACTURE

CO.,

LTD.";

-

In

2008,

HUILONG

wire

mesh

international

sales

department

successfully

obtained

European

market,

establishing

a

European

trading

circle

based

on

France,

Belgium

and

Italy;

-

In

2009,

we

obtained

50

acres

land

in

Taicheng

industry

park,

and

built

up

a

brandnew

factory.

The

workshop

occupies

25,000㎡,

warehouse

10000㎡,

with

total

300

sales

representatives

and

workers;

-

In

2011,

our

company

exported

to

more

than

one

hundred

countries,

cooperated

with

more

than

200

customers;

-

In

May

2012,

Shijiazhuang

international

trade

branch

office

was

set

up;

-

In

2013,

we

purchased

300㎡

of

office

building

in

Shijiazhuang;

-

In

2015,

Anping

HUILONG

Wire

Mesh

Manufacture

Co.,

Ltd

joined

the

Anping

Wire

Mesh

Chamber

of

Commerce,

becoming

an

important

part

of

it;

-

In

2016,

we

set

up

a

new

foreign

trade

team

of

35

people,

with

an

office

area

of

300

square

meters;

-

In

2017-2018,

our

wire

mesh

products

were

well

sold

and

well

recognized

in

the

markets

of

America,

Africa

and

Southeast

Asia;

-

In

2019,

we

registered

AIBUER

TRADING

CO.,

LTD.

and

integrated

more

factory

resources,

enriched

product

categories,

to

provide

customers

with

more

valuable

services;

-

In

2020,

HUILONG

invested

and

established

Concertina

Razor

Wire

Factory,

which

covers

an

area

of

7,000

square

meters;

-

In

2021,

the

factory

department

has

established

a

domestic

trade

team

of

30

people,

with

a

new

office

area

of

600

square

meters.