| Price | USD5.0-USD15.0/KG |

| MOQ | 50 COILS |

| Delivery Time | 7 DAYS AS SOON AS GET CUSTOMERS L/C OR DEPOSIT. |

| Brand | HUILONG |

| Place of Origin | CHINA HEBEI |

| Certification | CE CERTIFICATE / ISO |

| Model Number | CBW-HL001 |

| Packaging Details | IN COILS WITH WATERPROOF PAPER+WOVEN BAG; CARTON BOX; PALLET, ETC. |

| Payment Terms | L/C,T/T AT SIGHT |

| Supply Ability | 40,000 KG PER DAY |

| standard | ASTM, EN | Place of Origin | CHINA HEBEI |

| clip per spirl | 3,5,0 | Packaging Details | IN COILS WITH WATERPROOF PAPER+WOVEN BAG; CARTON BOX; PALLET, ETC. |

| Product Name | Galvanized Razor Wire Fence Stretched Barbed Wire Coils Weather Resistant Garden Fence Concertina | length | 8,10m as your request |

| Model Number | CBW-HL001 | Supply Ability | 40,000 KG PER DAY |

| Certification | CE CERTIFICATE / ISO | Brand Name | HUILONG |

| Payment Terms | L/C,T/T AT SIGHT | material | stainless steel,galvanized. |

| Price | USD5.0-USD15.0/KG | Delivery Time | 7 DAYS AS SOON AS GET CUSTOMERS L/C OR DEPOSIT. |

| wire diameter | 2.0,2.5,2.8mm | Minimum Order Quantity | 50 COILS |

| coil diamter | 300,450,500,600,700,900mm | tensile | 1400-1500MPA |

| Attribute | Value |

|---|---|

| Product Name | Galvanized Razor Wire Fence Stretched Barbed Wire Coils Weather Resistant Garden Fence Concertina |

| Material | Stainless steel, galvanized |

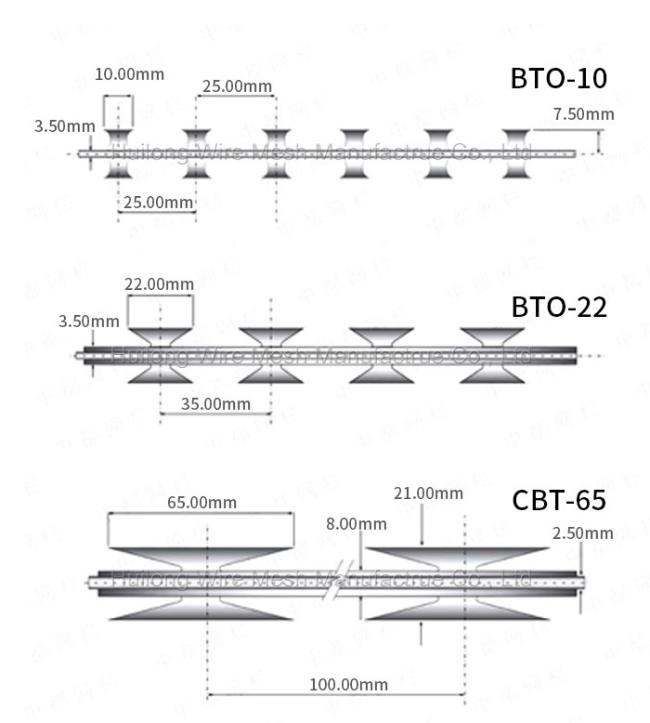

| Wire Diameter | 2.0, 2.5, 2.8mm |

| Coil Diameter | 300, 450, 500, 600, 700, 900mm |

| Clip Per Spiral | 3, 5, 0 |

| Length | 8, 10m (customizable) |

| Tensile Strength | 1400-1500MPA |

| Standard | ASTM, EN |

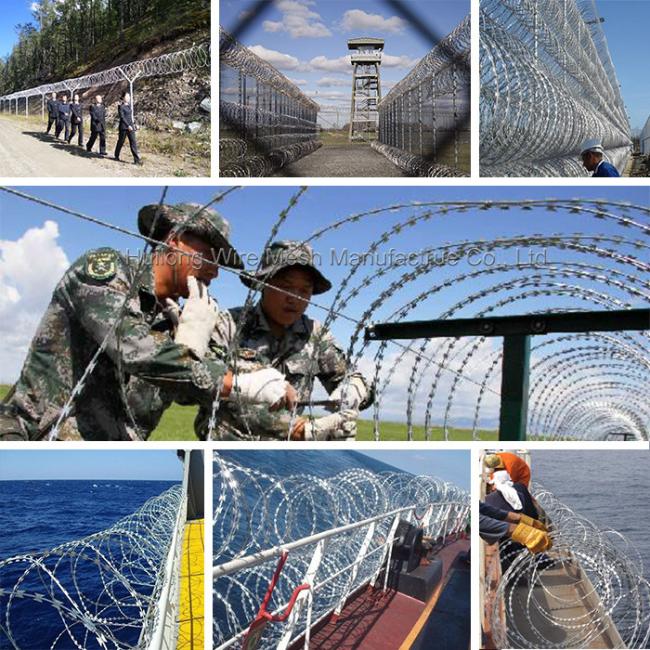

Concertina wires are coiled razor wires formed in coils, distinct from traditional barbed wires. While barbed wires are economical fencing options with sharp edges spaced at intervals, concertina wire fencing is more sophisticated, rigid, and capable of causing more severe injuries. As a result, concertina wires are used for high-security applications such as military bases, prisons, and electrical substations.

Due to the welding process, high quality, and strength, concertina wires are priced higher than barbed wires. Professional installation is required due to the sharp blades and high tensile nature.

Razor Barbed Wire can be PVC coated for enhanced corrosion resistance and aesthetic appeal. Standard green color is available, with custom colors available upon request.

Blades feature a high tensile reinforcing band for maximum strength, making them difficult to cut or trample. Our unique heavy-duty steel clips withstand approximately 200lbs/100kgs of force and cannot be parted by hand or standard tools.

| Coil Diameter | Loops | Clips | Length | Note |

|---|---|---|---|---|

| 300mm | 33 | 0 | 8-10m | Single coil |

| 450mm | 56 | 3 | 8-10m | Cross type |

| 500mm | 56 | 3 | 9-10m | Cross type |

| 600mm | 56 | 3 | 10-11m | Cross type |

| 700mm | 56 | 5 | 10-12m | Cross type |

| 900mm | 56 | 5 | 12-14m | Cross type |

Special attention is given to packaging due to the sharp blades:

Custom packaging solutions available upon request.

Our 5,000 square meter production facility includes:

We use pneumatic clip guns operating at 90-120psi (6-8bars, 60-80kg/cm) for fast, secure clip installation.

Our comprehensive quality control system covers:

International Standards Compliance:

Concertina Barbed Wire is widely used for high-security applications including:

Welded into diamond or rectangular mesh patterns for simple yet high-security structures, suitable for both private and commercial applications.

Combination of two different coil diameters with steel wires/ropes, offering the highest security grade available.

Rapid deployment trailers for effective layered concertina coil barriers (3 coils provide 1.7m high protection over 100m).

Individual loops pressed flat for direct attachment to existing fences without overhang.

All products undergo rigorous inspection before shipping, with documentation provided. Our after-sales service includes:

We are an 18-year manufacturer with our own trading company, combining production control with professional international trade services.

50 coils for standard products; customized products require negotiation. No MOQ for samples.

Our Quality Assurance Department implements strict inspections at every production stage, with 24-hour response and 72-hour resolution for any issues.