| Price | USD5.0-USD15.0/KG |

| MOQ | 50 COILS |

| Delivery Time | 7 DAYS AS SOON AS GET CUSTOMERS L/C OR DEPOSIT. |

| Brand | HUILONG |

| Place of Origin | CHINA |

| Certification | CE CERTIFICATE / ISO |

| Model Number | CBW-HL001 |

| Packaging Details | IN COILS WITH WATERPROOF PAPER+WOVEN BAG; CARTON BOX; PALLET, ETC. |

| Payment Terms | L/C,T/T AT SIGHT |

| Supply Ability | 40,000 KG PER DAY |

| Place of Origin | CHINA | Tensile | 1400-1500MPA |

| Packaging Details | IN COILS WITH WATERPROOF PAPER+WOVEN BAG; CARTON BOX; PALLET, ETC. | Product Name | Ribbon Style 450mm Coil Diameter Straight Line Concertina Razor Wire For Protection |

| Material | Galvanized, Stainless Steel | Standard | ASTM A975, EN |

| Model Number | CBW-HL001 | Supply Ability | 40,000 KG PER DAY |

| Certification | CE CERTIFICATE / ISO | Coil diamter | 300,500,700,900mm |

| Clip per spirl | 3,5,0 | Brand Name | HUILONG |

| Payment Terms | L/C,T/T AT SIGHT | Wire diameter | 2.0,2.5,2.8mm |

| Price | USD5.0-USD15.0/KG | Delivery Time | 7 DAYS AS SOON AS GET CUSTOMERS L/C OR DEPOSIT. |

| Length | 8,10m as your request | Minimum Order Quantity | 50 COILS |

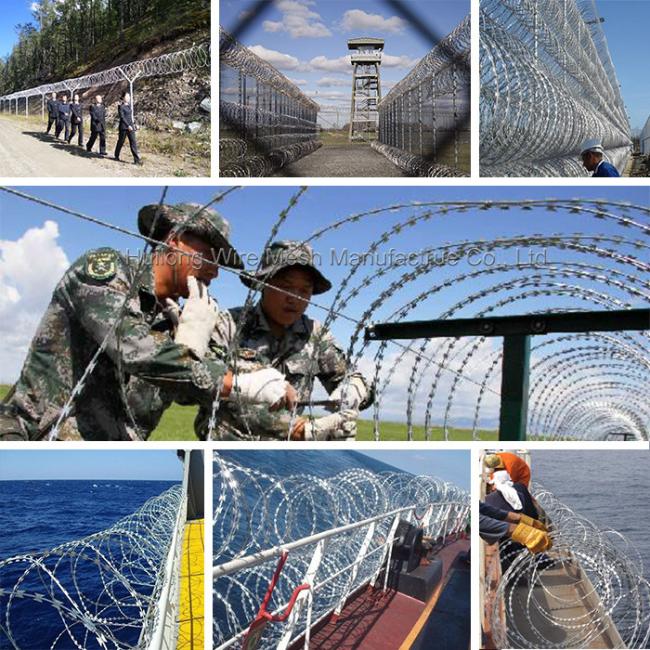

High-security concertina razor wire formed in large coils that can be expanded for perimeter protection. Available in galvanized steel or stainless steel construction for durability and corrosion resistance.

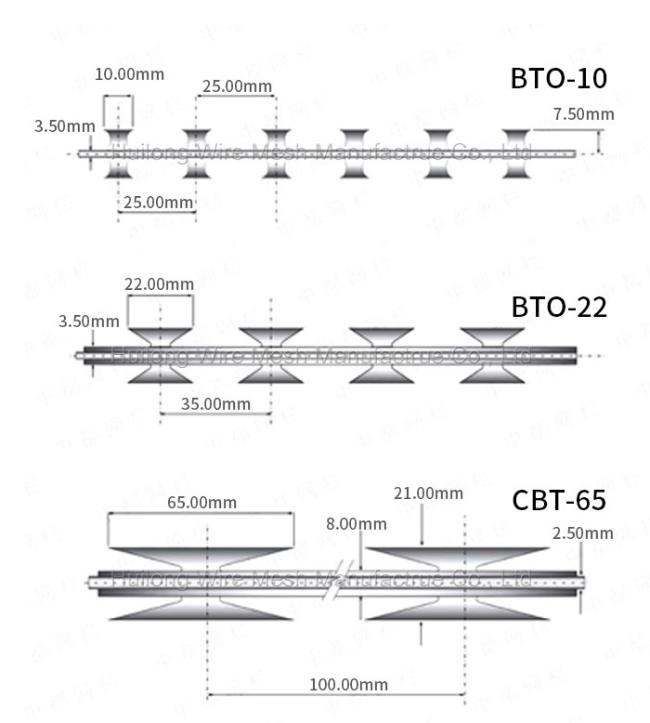

| Product Name | Ribbon Style 450mm Coil Diameter Straight Line Concertina Razor Wire For Protection |

| Material | Galvanized, Stainless Steel |

| Wire diameter | 2.0, 2.5, 2.8mm |

| Coil diameter | 300, 500, 700, 900mm |

| Clip per spiral | 3, 5, 0 |

| Length | 8, 10m (customizable) |

| Tensile | 1400-1500MPA |

| Standard | ASTM A975, EN |

Features high tensile reinforcing band for maximum strength and heavy-duty steel clips that withstand approximately 200lbs/100kgs of force.

| Coil diameter | Loops | Clips | Length | Note |

|---|---|---|---|---|

| 300mm | 33 | 8-10m | Single coil | |

| 450mm | 56 | 3 | 8-10m | Cross type |

| 500mm | 56 | 3 | 9-10m | Cross type |

| 600mm | 56 | 3 | 10-11m | Cross type |

| 700mm | 56 | 5 | 10-12m | Cross type |

| 900mm | 56 | 5 | 12-14m | Cross type |

5,000 square meter production facility with 5 punching machines, 20 wire wrapping machines, and 50 automatic pneumatic clip guns. Staff of 68 including dedicated quality inspectors.

Comprehensive quality control system covering raw materials, production processes, and final inspection. Complies with international standards:

Widely used for high-security perimeter protection in:

We are an 18-year manufacturer with our own factory and registered trading company, combining production control with professional international trade services.

50 coils for standard products; customized orders negotiable. No minimum for samples.

Strict quality control at all production stages with dedicated QA department. 24-hour response time for any issues.