| Price | USD5.0-USD15.0/KG |

| MOQ | 50 COILS |

| Delivery Time | 7 DAYS AS SOON AS GET CUSTOMERS L/C OR DEPOSIT. |

| Brand | HUILONG |

| Place of Origin | CHINA HEBEI |

| Certification | CE CERTIFICATE / ISO |

| Model Number | CBW-HL001 |

| Packaging Details | IN COILS WITH WATERPROOF PAPER+WOVEN BAG; CARTON BOX; PALLET, ETC. |

| Payment Terms | L/C,T/T AT SIGHT |

| Supply Ability | 40,000 KG PER DAY |

| Place of Origin | CHINA HEBEI | Tensile | 1400-1500MPA |

| Packaging Details | IN COILS WITH WATERPROOF PAPER+WOVEN BAG; CARTON BOX; PALLET, ETC. | Product Name | Ukraine Military Use Galvanized 1000mm BTO16 BTO18 Galvanized Razor Barbed Wire Fence |

| Material | stainless steel,galvanized. | Standard | ASTM A975, EN |

| Model Number | CBW-HL001 | Supply Ability | 40,000 KG PER DAY |

| Certification | CE CERTIFICATE / ISO | Coil diamter | 300mm 450mm 500mm 700mm 900mm 1000mm Customized |

| Clip per spirl | 0 3 5 | Brand Name | HUILONG |

| Payment Terms | L/C,T/T AT SIGHT | Wire diameter | 2.0,2.5,2.8mm |

| Price | USD5.0-USD15.0/KG | Delivery Time | 7 DAYS AS SOON AS GET CUSTOMERS L/C OR DEPOSIT. |

| Length | 8,10m as your request | Minimum Order Quantity | 50 COILS |

| Attribute | Value |

|---|---|

| Product Name | Ukraine Military Use Galvanized 1000mm BTO16 BTO18 Galvanized Razor Barbed Wire Fence |

| Material | Stainless steel, galvanized |

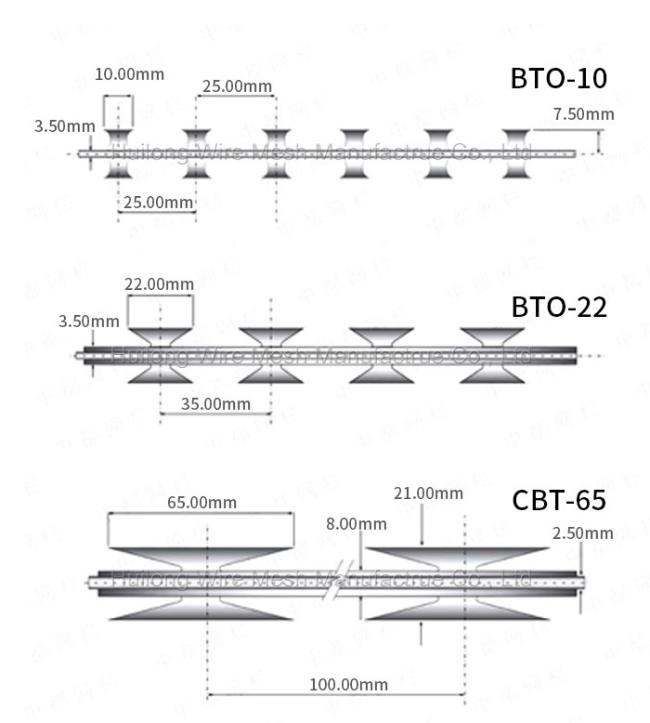

| Wire diameter | 2.0, 2.5, 2.8mm |

| Coil diameter | 300mm, 450mm, 500mm, 700mm, 900mm, 1000mm (Customized available) |

| Clip per spiral | 0, 3, 5 |

| Length | 8m, 10m (Customizable) |

| Tensile | 1400-1500MPA |

| Standard | ASTM A975, EN |

Optional PVC coating provides higher corrosion resistance and aesthetic appeal. Standard green color available with custom color options.

Features high tensile reinforcing band for maximum strength and unique heavy duty steel clips (withstands ~200lbs/100kgs force).

| Coil diameter | Loops | Clips | Length | Note |

|---|---|---|---|---|

| 300mm | 33 | - | 8-10m | Single coil |

| 450mm | 56 | 3 | 8-10m | Cross type |

| 500mm | 56 | 3 | 9-10m | Cross type |

| 600mm | 56 | 3 | 10-11m | Cross type |

| 700mm | 56 | 5 | 10-12m | Cross type |

| 900mm | 56 | 5 | 12-14m | Cross type |

Comprehensive quality control system covering raw materials, production, inspection, packaging and transportation. Compliant with international standards:

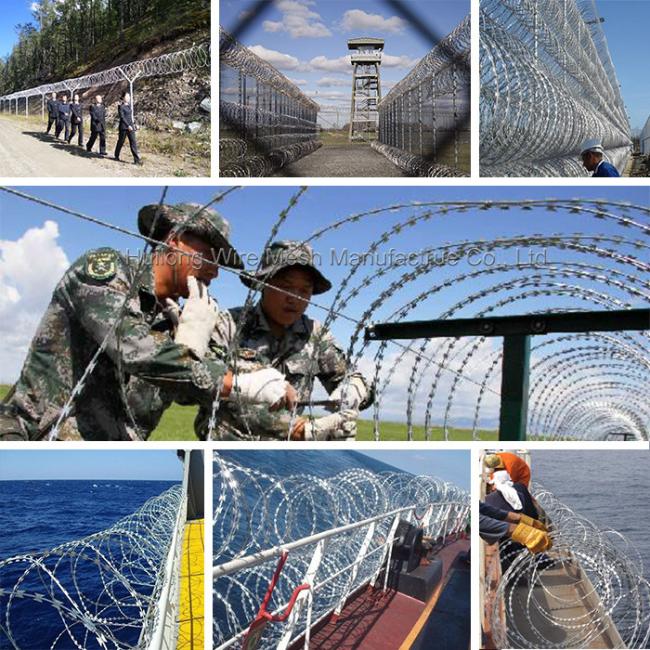

Widely used in high-security installations worldwide including:

Diamond or rectangular mesh patterns for high-security applications, can be attached to frames or existing fences.

Combination of two different coil diameters for highest security grade applications.

Trailer-mounted rapid deployment system (3-coil configuration provides 1.7m high protection for 100m).

Flattened loops ideal for fence topping without overhang.

Rigorous pre-shipment inspection by factory and customer-designated inspectors. Documentation provided for all quality checks.

We are an 18-year manufacturer with trading capabilities, combining quality control with professional international trade services.

50 coils for standard products, negotiable for custom orders. No MOQ for samples.

Strict quality control at all production stages, international standard compliance, and 24/7 support commitment.