| Price | USD5.0-USD15.0/KG |

| MOQ | 50 COILS |

| Delivery Time | 7 DAYS AS SOON AS GET CUSTOMERS L/C OR DEPOSIT. |

| Brand | HUILONG |

| Place of Origin | CHINA HEBEI |

| Certification | CE CERTIFICATE / ISO |

| Model Number | CBW-HL001 |

| Packaging Details | IN COILS WITH WATERPROOF PAPER+WOVEN BAG; CARTON BOX; PALLET, ETC. |

| Payment Terms | L/C,T/T AT SIGHT |

| Supply Ability | 40,000 KG PER DAY |

| Place of Origin | CHINA HEBEI | Tensile | 1400-1500MPA |

| Packaging Details | IN COILS WITH WATERPROOF PAPER+WOVEN BAG; CARTON BOX; PALLET, ETC. | Product Name | Ukraine Military Use Galvanized 1000mm BTO16 BTO18 Galvanized Razor Barbed Wire Fence |

| Material | stainless steel,galvanized. | Standard | ASTM A975, EN |

| Model Number | CBW-HL001 | Supply Ability | 40,000 KG PER DAY |

| Certification | CE CERTIFICATE / ISO | Coil diamter | 300mm 450mm 500mm 700mm 900mm 1000mm Customized |

| Clip per spirl | 0 3 5 | Brand Name | HUILONG |

| Payment Terms | L/C,T/T AT SIGHT | Wire diameter | 2.0,2.5,2.8mm |

| Price | USD5.0-USD15.0/KG | Delivery Time | 7 DAYS AS SOON AS GET CUSTOMERS L/C OR DEPOSIT. |

| Length | 8,10m as your request | Minimum Order Quantity | 50 COILS |

| Attribute | Value |

|---|---|

| Product Name | Ukraine Military Use Galvanized 1000mm BTO16 BTO18 Galvanized Razor Barbed Wire Fence |

| Material | Stainless steel, galvanized |

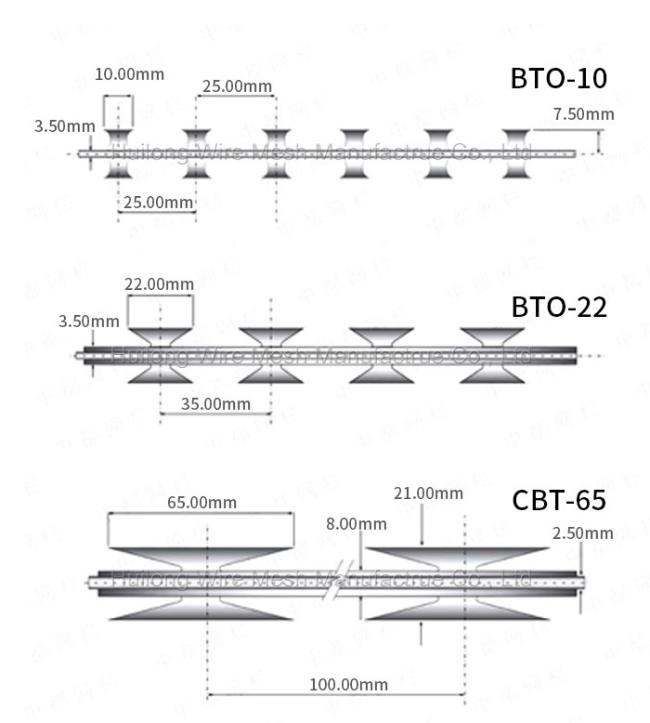

| Wire diameter | 2.0, 2.5, 2.8mm |

| Coil diameter | 300mm, 450mm, 500mm, 700mm, 900mm, 1000mm (Customized available) |

| Clip per spiral | 0, 3, 5 |

| Length | 8m, 10m (Customizable) |

| Tensile | 1400-1500MPA |

| Standard | ASTM A975, EN |

Blade barbed wire is a high-security protection product that fixes sharp blades on high-strength steel wire or rope through a specialized process. The blades are manufactured from premium stainless steel or alloy steel, offering exceptional hardness and corrosion resistance to maintain sharpness in harsh environments. Evenly distributed along the rope, these blades create an impenetrable barrier that effectively deters trespassing with serious cutting risk.

Our blades feature a high-tensile reinforcing band for maximum strength, substantially more resistant to cutting or trampling. The unique heavy-duty steel clips withstand approximately 200lbs/100kgs of force, requiring specialized tools for removal.

| Coil diameter | Loops | Clips | Length | Note |

|---|---|---|---|---|

| 300mm | 33 | - | 8-10m | Single coil |

| 450mm | 56 | 3 | 8-10m | Cross type |

| 500mm | 56 | 3 | 9-10m | Cross type |

| 600mm | 56 | 3 | 10-11m | Cross type |

| 700mm | 56 | 5 | 10-12m | Cross type |

| 900mm | 56 | 5 | 12-14m | Cross type |

Our 5,000 square meter production facility includes 5 punching machines, 20 wire wrapping machines, and 50 automatic pneumatic clip guns. With 68 skilled workers including dedicated quality inspectors, we maintain strict quality control throughout production. Our pneumatic clip guns operate at 90-120psi (6-8bars) for fast, secure clip installation.

Our comprehensive quality management system covers every stage from raw materials to final shipment. We adhere to international standards including ASTM F1910-98, ASTM F1379-95, and ASTM F1911-05 for barbed tape obstacles. Our dedicated after-sales team ensures prompt resolution of any issues.

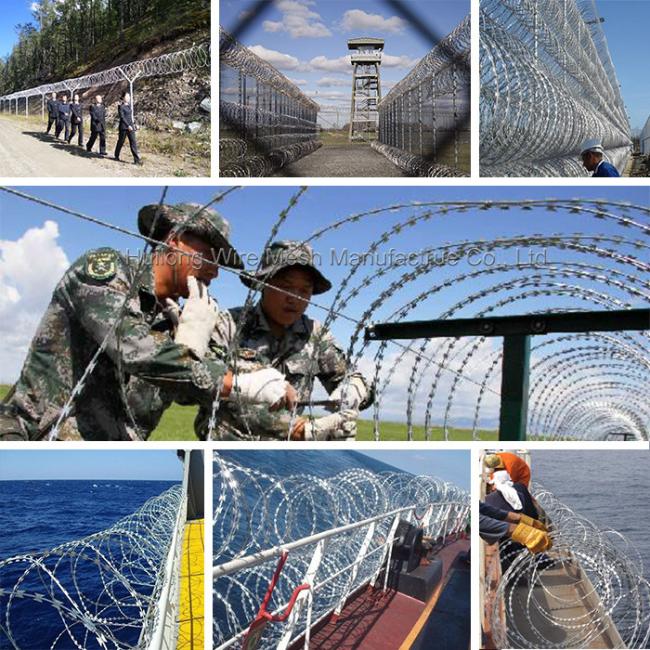

Concertina Barbed Wire is widely used for high-security applications including:

We operate as both an 18-year manufacturing facility and a professional trading company. This dual structure allows us to maintain strict quality control while offering comprehensive product sourcing services.

Minimum order quantity is 50 coils for standard products. Custom products require negotiation. Sample orders have no MOQ requirements.

Our Quality Assurance Department implements strict inspections at every production stage. We guarantee response within 24 hours and resolution within 72 hours for any quality concerns.