| Price | USD5.0-USD15.0/KG |

| MOQ | 50 COILS |

| Delivery Time | 7 DAYS AS SOON AS GET CUSTOMERS L/C OR DEPOSIT. |

| Brand | HUILONG |

| Place of Origin | CHINA HEBEI |

| Certification | CE CERTIFICATE / ISO |

| Model Number | CBW-HL001 |

| Packaging Details | IN COILS WITH WATERPROOF PAPER+WOVEN BAG; CARTON BOX; PALLET, ETC. |

| Payment Terms | L/C,T/T AT SIGHT |

| Supply Ability | 40,000 KG PER DAY |

| Place of Origin | CHINA HEBEI | Tensile | 1400-1500MPA |

| Packaging Details | IN COILS WITH WATERPROOF PAPER+WOVEN BAG; CARTON BOX; PALLET, ETC. | Product Name | Ukraine Military Use Galvanized 1000mm BTO16 BTO18 Galvanized Razor Barbed Wire Fence |

| Material | stainless steel,galvanized. | Standard | ASTM A975, EN |

| Model Number | CBW-HL001 | Supply Ability | 40,000 KG PER DAY |

| Certification | CE CERTIFICATE / ISO | Coil diamter | 300mm 450mm 500mm 700mm 900mm 1000mm Customized |

| Clip per spirl | 0 3 5 | Brand Name | HUILONG |

| Payment Terms | L/C,T/T AT SIGHT | Wire diameter | 2.0,2.5,2.8mm |

| Price | USD5.0-USD15.0/KG | Delivery Time | 7 DAYS AS SOON AS GET CUSTOMERS L/C OR DEPOSIT. |

| Length | 8,10m as your request | Minimum Order Quantity | 50 COILS |

| Attribute | Value |

|---|---|

| Product Name | Ukraine Military Use Galvanized 1000mm BTO16 BTO18 Galvanized Razor Barbed Wire Fence |

| Material | stainless steel, galvanized |

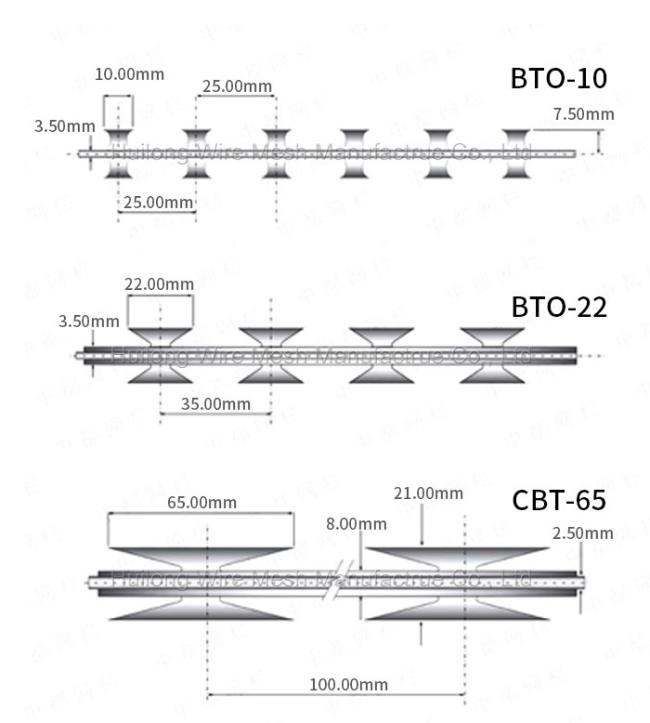

| Wire diameter | 2.0, 2.5, 2.8mm |

| Coil diameter | 300mm 450mm 500mm 700mm 900mm 1000mm Customized |

| Clip per spiral | 0 3 5 |

| Length | 8, 10m as your request |

| Tensile | 1400-1500MPA |

| Standard | ASTM A975, EN |

Blade barbed wire is a kind of safety protection product which fixes sharp blade on high strength steel wire or rope by special process. These blades are usually made of high-quality stainless steel or alloy steel, with extremely high hardness and corrosion resistance, and are able to stay sharp for a long time in harsh environments. The blades are evenly distributed along the rope, creating an impenetrable barrier, and any attempt to climb or cross will face a serious risk of cutting, effectively deterring trespassing.

We are an oversized factory floor, about 37 years old and one of the largest razor factories in our local market.

Blade is manufactured with a high tensile reinforcing band providing maximum strength. This reinforcing band is substantially more difficult to cut or trample. In addition, we incorporate a unique heavy duty steel clip designed to withstand a force of approx. 200lbs/100kgs, which cannot be parted by hand or with standard tools.

| Coil diameter | Loops | Clips | Length | Note |

|---|---|---|---|---|

| 300mm | 33 | 8-10m | Single coil | |

| 450mm | 56 | 3 | 8-10m | Cross type |

| 500mm | 56 | 3 | 9-10m | Cross type |

| 600mm | 56 | 3 | 10-11m | Cross type |

| 700mm | 56 | 5 | 10-12m | Cross type |

| 900mm | 56 | 5 | 12-14m | Cross type |

Because Concertina Barbed Wire has sharp blades, it is necessary to pay more attention to the way of packaging.

The production workshop of Concertina Barbed Wire occupies an area of 5,000 square meters, with 5 punching machines, 20 wire wrapping machines, 50 automatic pneumatic clip guns for clip installation, and 6 workbenches for manual buckle. There are 68 workers in total, including 1 Warehouse Manager and 2 Quality Inspectors.

We use pneumatic clip gun to install C-ring clips. Air press: 90-120psi (6-8bars, 60-80kg/cm). Faster and stronger.

Quality management is a part we consider very important, because it directly determines whether the customer is satisfied or not. From raw material storage, machine maintenance, workers' qualifications, technical standards, production process, to product inspection, packaging and transportation, we ensure quality control to meet customers' requirements at the most economical level.

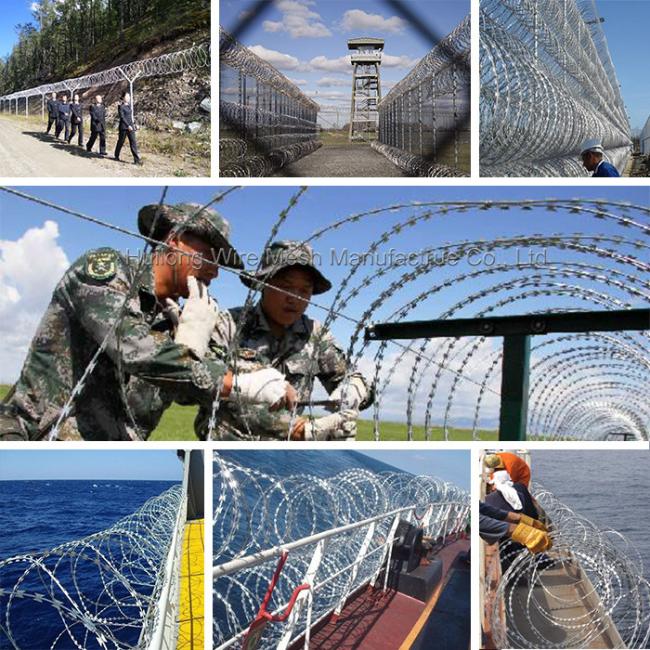

Concertina Barbed Wire has beautiful, economical, and practical, good anti-obstruction effect, convenient construction and other excellent characteristics. Currently, Razor Barbed Wire has been widely used in many countries, such as industrial and mining enterprises, garden apartments, border posts, military fields, prisons, detention houses, government buildings and other high security facilities.

Welded razor wires into meshes with diamond or rectangular hole patterns. It has simple but high security structure for both private and commercial applications. Welded razor wire can be attached or welded onto the frame as security fence. It can also be used as additional security measure for other security fences.

Double concertina razor wire is combined with two different coil diameter of razor wire with steel wires or steel ropes. It is the advancement of common concertina wires. It has the highest security grade among all types of razor wires. It is suitable for use where need highest grade of security purpose.

Mobile razor wire deployment system is designed for rapid deployment of effectively layered concertina coils. This is serious obstacle for rebels or demonstrators and vehicles to gain entry. Razor wire trailer deployment trailers are available in 3 coil configuration (3 coil = gives 1.7m high protection for 100m distance).

Flat loop concertina wire consists of individual loops of barb tape. Press the single coil razor wire into flat or press the two loops into flat and then expand them across. Flat warp concertina wire can be attached directly onto the top of an existing fence or gate.

Perfect quality control system can ensure the delivery of goods on time. After completing the mass production, quality inspectors of our factory and the inspectors designated by the customers will check and test the products to ensure that the quality and quantity meet customers' requirements.

We are a 18-year factory and we have registered trading company for sourcing more valuable products for the customers. Therefore, we have both the advantages of factory and trading company. We have our own factory, so we can control the product quality timely and efficiently.

MOQ is 50 coils for common standardized products and ready stock; For Customized Products, MOQ should be negotiated in advance. There is no MOQ for sample orders.

We have established the Department of Quality Assurance, every steps from raw material preparation to final product, we have strict quality inspection system to ensure the products meet international standards and satisfy customers.