Military

Concertina

Blade

Barbed

Fence

Security

Razor

Barbed

Wire

Product

Specifications

|

Attribute

|

Value

|

|

Material

|

Stainless

steel,

galvanized

|

|

Wire

diameter

|

2.0,

2.5,

2.8mm

|

|

Coil

diameter

|

300mm,

450mm,

500mm,

700mm,

900mm,

1000mm

(Customized

available)

|

|

Clip

per

spiral

|

0,

3,

5

|

|

Length

|

8m,

10m

(Custom

lengths

available)

|

|

Tensile

strength

|

1400-1500MPA

|

|

Standard

|

ASTM

A975,

EN

|

Product

Overview

Razor

barbed

wire

fences

are

essential

security

solutions

for

military

installations,

government

facilities,

and

high-security

areas.

Designed

to

deter

and

prevent

unauthorized

access,

these

fences

feature

sharp,

pointed

steel

blades

that

provide

superior

protection

compared

to

traditional

barbed

wire.

Material

Composition

Blade

Specifications

-

Material:

Galvanized

Steel

or

Stainless

Steel

-

Thickness:

0.5mm

-

Barb

Length:

12-65mm

-

Barb

Spacing:

26-100mm

Core

Wire

-

Material:

Electro

Galvanized

Wire,

Hot-dipped

Galvanized

Wire,

Stainless

Steel

Wire

-

Wire

Diameter:

2.5mm

PVC

Coating

Option

Available

with

PVC

coating

for

enhanced

corrosion

resistance

and

aesthetic

appeal.

Standard

color

is

green

(RAL

6005),

with

custom

colors

available

upon

request.

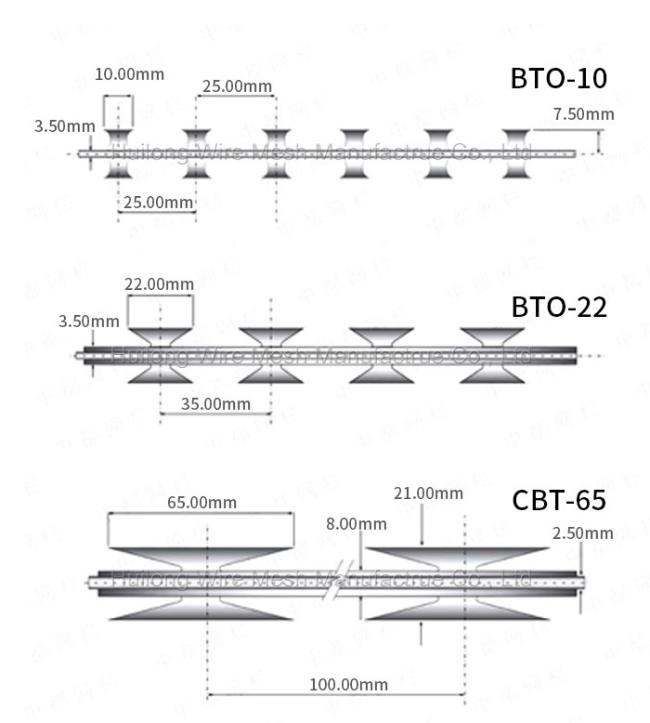

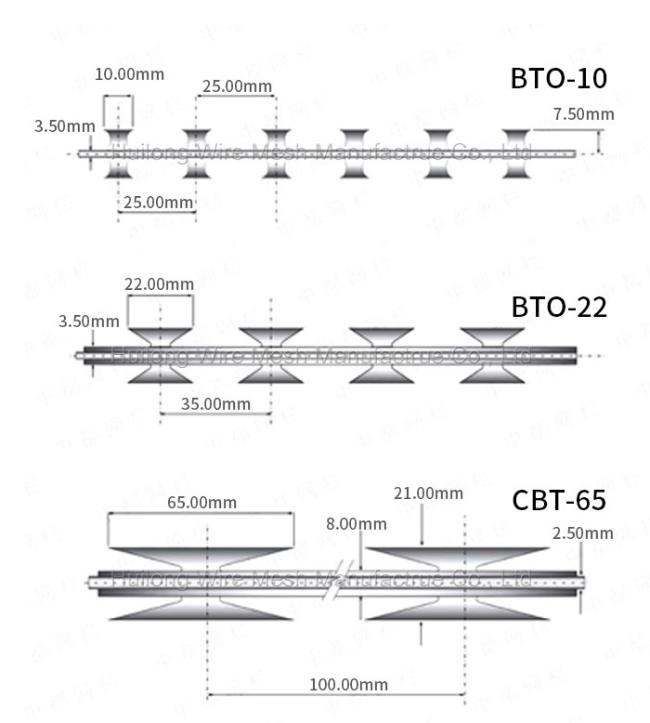

Blade

Types

-

BTO

(Barbed

Tape

Obstacle):

BTO-10,

BTO-18,

BTO-16,

BTO-22,

BTO-30

-

CBT

(Concertina

Barbed

Tape):

CBT-60,

CBT-65

Our

blades

feature

a

high-tensile

reinforcing

band

for

maximum

strength,

resistant

to

cutting

or

trampling.

The

heavy-duty

steel

clips

withstand

approximately

200lbs/100kgs

of

force,

requiring

specialized

tools

for

removal.

Standard

Specifications

|

Coil

diameter

|

Loops

|

Clips

|

Length

|

Note

|

|

300mm

|

33

|

-

|

8-10m

|

Single

coil

|

|

450mm

|

56

|

3

|

8-10m

|

Cross

type

|

|

500mm

|

56

|

3

|

9-10m

|

Cross

type

|

|

600mm

|

56

|

3

|

10-11m

|

Cross

type

|

|

700mm

|

56

|

5

|

10-12m

|

Cross

type

|

|

900mm

|

56

|

5

|

12-14m

|

Cross

type

|

Manufacturing

Process

-

Raw

Material

Preparation:

Galvanized/Stainless

Steel

Plate

+

Wire

-

Machine

Punching:

Steel

sheet

punched

into

sharp

barbs

-

Machine

Forming:

Core

wire

and

razor

plate

assembly

-

Clip

Installation:

C-ring

clips

applied

with

pneumatic

clip

gun

-

PVC

Coating:

Optional

color

coating

application

-

Packaging:

Custom

packaging

solutions

Packaging

Options

-

Standard

Packaging:

Waterproof

paper

+

woven

bag

(loose

or

compressed

with

steel

belts)

-

Retail

Packaging:

Small

corrugated

boxes

for

individual

coils

-

Bulk

Packaging:

Custom

corrugated

cartons

for

3-5

coils

-

Palletized:

Compressed

coils

with

plastic

film

and

packing

belts

-

Custom

Solutions:

Exclusive

packaging

per

customer

requirements

Production

Capacity

Our

5,000

square

meter

production

facility

features

5

punching

machines,

20

wire

wrapping

machines,

and

50

automatic

pneumatic

clip

guns.

With

68

skilled

workers

including

dedicated

quality

inspectors,

we

maintain

strict

quality

control

throughout

the

manufacturing

process.

Quality

Assurance

Our

comprehensive

quality

management

system

covers

every

stage

from

raw

materials

to

final

shipment.

We

adhere

to

international

standards

including:

-

ASTM

F1910-98(2018):

Standard

Specification

for

Long

Barbed

Tape

Obstacles

-

ASTM

F1379-95(2018):

Standard

Terminology

Relating

to

Barbed

Tape

-

ASTM

F1911-05(2019):

Standard

Practice

for

Installation

of

Barbed

Tape

Applications

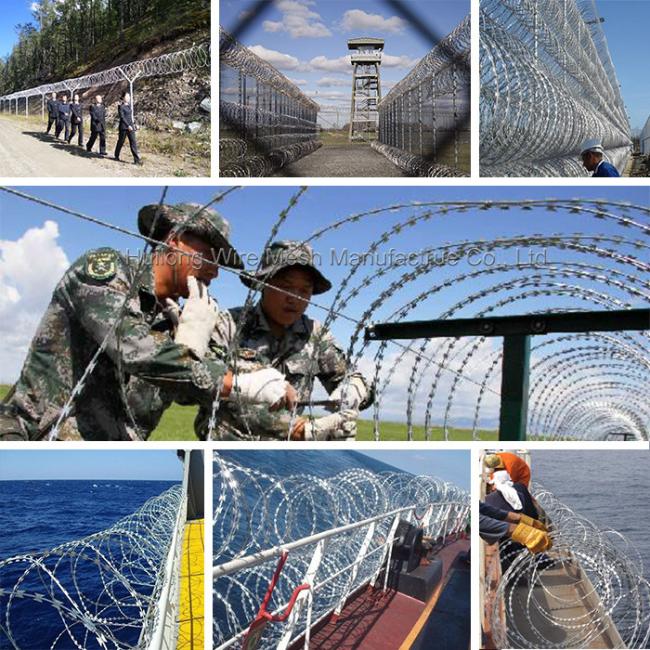

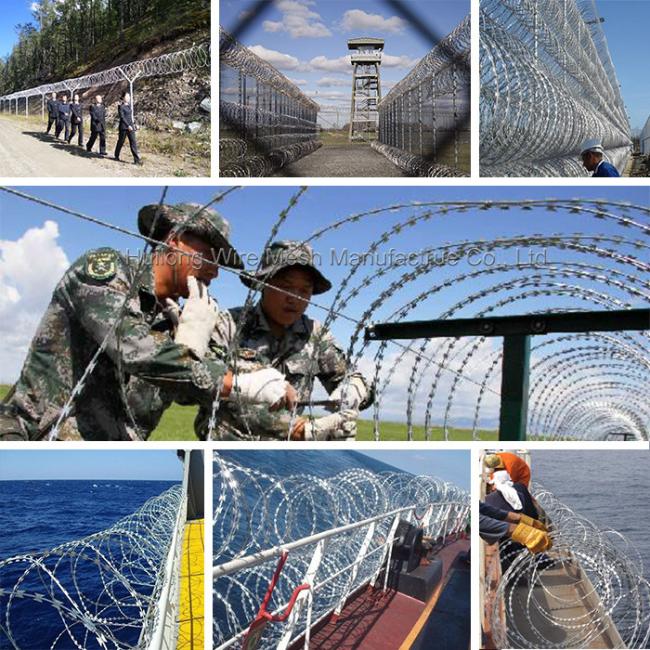

Our

concertina

barbed

wire

is

widely

used

for

high-security

applications

worldwide,

including:

-

Military

installations

and

border

security

-

Prisons

and

detention

facilities

-

Government

buildings

and

sensitive

sites

-

Industrial

complexes

and

private

properties

Advanced

Security

Solutions

Welded

Razor

Wire

Meshes

Diamond

or

rectangular

pattern

meshes

for

enhanced

security,

suitable

for

attachment

to

existing

fences

or

frames.

Double

Concertina

Razor

Wire

Combined

coils

of

different

diameters

for

maximum

security

grade

applications.

Mobile

Deployment

Systems

Rapid

deployment

trailers

for

temporary

security

barriers

(3-coil

configuration

provides

1.7m

high

protection

over

100m).

Flat

Loop

Concertina

Wire

Ideal

for

fence

topping

with

minimal

overhang,

pressed

flat

for

direct

attachment

to

existing

structures.

Quality

Inspection

Process

Prior

to

shipment,

our

quality

inspectors

and

customer-designated

representatives

conduct

thorough

testing

to

ensure

product

specifications

are

met.

Detailed

inspection

reports

are

provided

for

customer

review.

After-Sales

Service

-

Regular

production

schedule

updates

-

24-hour

response

time

for

all

inquiries

-

72-hour

problem

resolution

guarantee

-

Comprehensive

quality

issue

resolution

-

Prompt

handling

of

post-delivery

concerns

Frequently

Asked

Questions

Are

you

a

factory

or

trading

company?

We

are

an

18-year

manufacturing

facility

with

dedicated

trading

operations.

This

dual

structure

allows

us

to

maintain

strict

quality

control

while

providing

professional

international

trade

services.

What's

the

minimum

order

quantity?

Standard

products:

50

coils

minimum.

Custom

products:

negotiable.

No

MOQ

for

sample

orders.

How

do

you

guarantee

product

quality?

Our

Quality

Assurance

Department

implements

strict

inspections

at

every

production

stage.

We

adhere

to

international

standards

and

provide

24/7

support

with

guaranteed

72-hour

resolution

for

any

issues.

Company

History

1989:

Company

established

in

Anping

Wire

Mesh

World

Supermarket

1994:

Founded

Anping

HUILONG

wire

mesh

factory

1998:

Began

international

cooperation

2004:

Became

joint

venture

company

2008:

Expanded

to

European

markets

2009:

Built

new

50-acre

factory

complex

2011:

Exported

to

over

100

countries

2012:

Established

Shijiazhuang

branch

office

2015:

Joined

Anping

Wire

Mesh

Chamber

of

Commerce

2016:

Expanded

foreign

trade

team

2020:

Established

dedicated

Concertina

Razor

Wire

Factory

2021:

Expanded

domestic

trade

operations